You care about both quality and efficiency on your manufacturing line (or your production floor or your workshop or whatever you call it!) But did you know that these two aims are not always at odds? Many small business owners assume that they are, that speed necessarily comes at the expense of quality and vice versa. But actually, the two can have synergistic effects in many cases.

Enter Lean Six Sigma

First codified in the early 2000s, Lean Six Sigma combines ideas from the quality-improvement philosophy Six Sigma with ideas from the efficiency-focused Lean manufacturing philosophies. (There are several different Lean philosophies. An example we discussed recently is the Toyota Production System.) Six Sigma primarily improves quality by reducing variability in a manufacturing process so that fewer parts have to be thrown out. Lean manufacturing improves speed (lead time) and profit by reducing inefficiency, primarily in the form of excess inventory.

Rhonda had already heard of both Lean and Six Sigma…

If you’re a regular here at Zattatat, you know that Rhonda is a retired RN who now runs a business making and selling wooden items. Her most popular is the Gnome-Shaped Wooden Beer Mug.

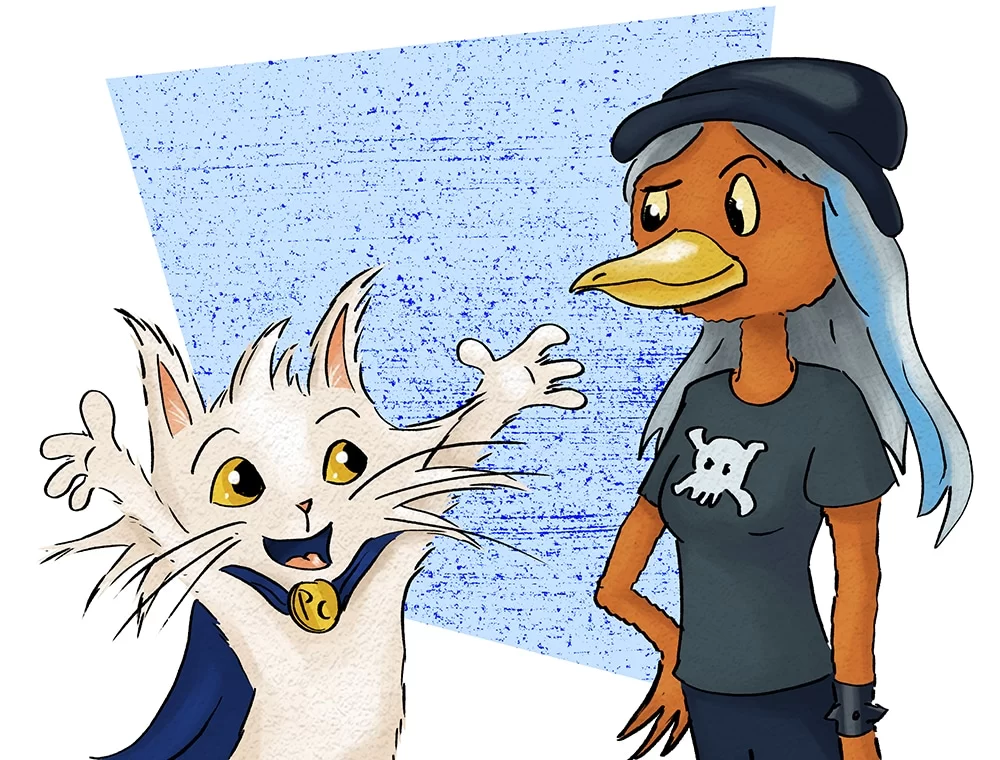

Recently, Rhonda had been lucky to find a break from immediate manufacturing-related emergencies, and had been able to spend some time learning about higher-level strategies that she can use to scale and improve her business. So having already heard about both Lean and Six Sigma, Rhonda was skeptical when her friend Process Cat brought up Lean Six Sigma.

A valid question, but Process Cat explained that Lean Six Sigma has some of its own unique insights that would not have been found by either philosophy on its own. And in his opinion, the most important of those is…

Time Traps

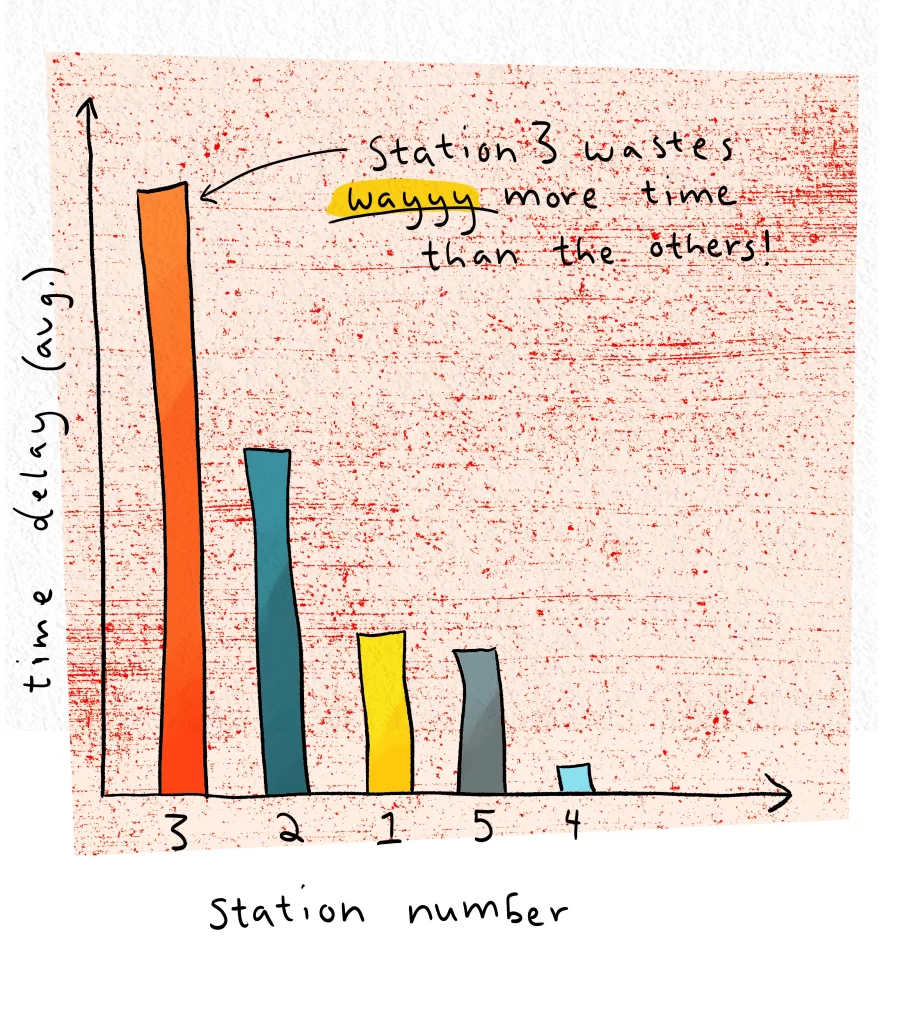

Typically, you’ll find that a small percentage of the workstations (like the CNC machining station or the painting station in Rhonda’s example) cause the vast majority of delays in your manufacturing process.

If you’re familiar with the Pareto Principle, this will come as no surprise. And in Lean Six Sigma, these “troublemaker” workstations are known as Time Traps. And when the delays are caused by time that needs to be spent finding or fixing quality problems (which they often are)…

Six Sigma and Lean work together!

Specifically, by applying Six Sigma very aggressively to the time trap workstations, you can reduce the amount of time wasted at those stations and thereby reduce the amount of inventory that sits waiting at those stations. In this way you’re improving the quality and efficiency of your manufacturing line!

Well Rhonda, yes it would and you should work towards that in the long run. But in a situation with limited resources to direct towards implementing Six Sigma, you’ll get far more “bang for your buck” by focusing first on the stations that are causing most of your problems. And we know that you have limited resources because there are only 24 hours in a day…

Weekly Challenge:

Look through your own business – do you know what your time traps are? If not, make it a New Years resolution to find them!