Everyone knows what Process Variability is and what causes it.

Just kidding. Most people don’t.

But they should if they’re running any kind of making/manufacturing/producing business.

Process Variability: Manufacturers’ Nemesis

Yeah, honestly, life would be a lot easier without process variability.

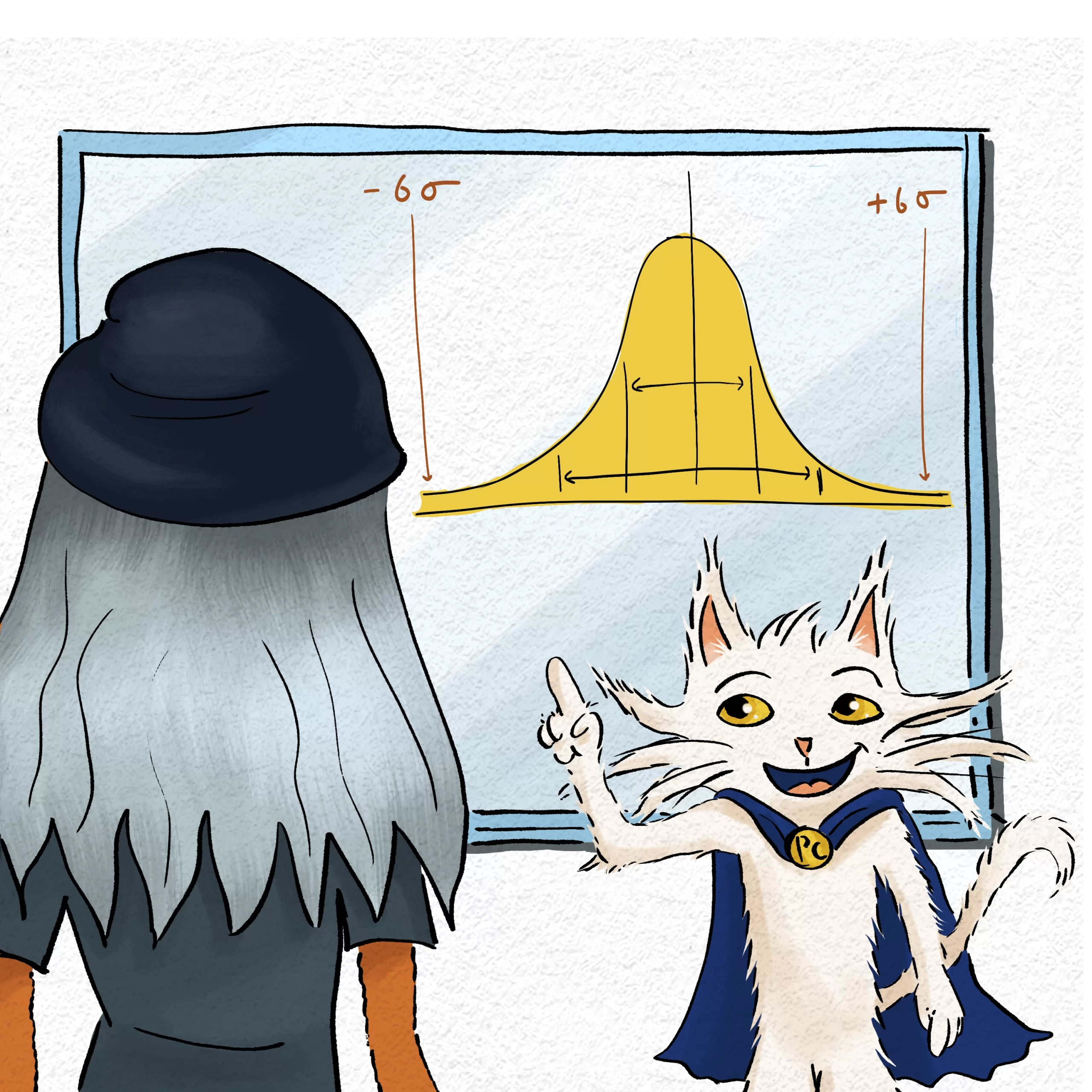

Process variability is just what it sounds like: we think we do the same process the same way over and over again… but actually, we don’t get exactly the same result every time! And the reason is statistical fluctuation. Just as every snowflake, every tree, or every wave in the ocean is different, every product we make ends up being a tiny bit different from any other product we’ve made.

This is beautiful when it comes to trees, waves, and snowflakes. (And, to a certain extent, that’s part of the appeal of handmade products.) But it becomes a problem when that variability happens to affect the function of our product.

Rhonda learned this the hard way…

If you’re a regular PCat reader, you know that Rhonda is a retired nurse who now runs a business making and selling wooden items like coasters and beer mugs. And if you read our (link: last article), you also know that she recently had some problems with her coasters. Specifically, some of them weren’t coming out flat!

So she asked her friend Process Cat for some help.

Once inside, Rhonda explained the problem with her coasters: she and her one part-time employee (a local high school kid named Nathan) did the process the exact same way every time, using the same species of wood, from the same supplier… but sometimes, the coasters were thick. Sometimes they were thin. And sometimes, part of the coaster was thick while other parts were thin! (That part was the problem. People who pay a premium for handmade wooden coasters don’t like it when the coaster causes them to spill their beer, apparently.)

Anyway

At Process Cat’s suggestion, the first thing they checked was Rhonda’s work instructions. Was everything being done exactly the way it was written down? Had any innocent-seeming “off-the-book” changes been made? (Like using a new type of varnish?) Were there any ambiguities in the instructions that could lead to Rhonda’s coasters coming out different from Nathan’s?

Satisfied that the problem wasn’t people or materials, Process Cat next recommended that they check the equipment. Was the bandsaw due for maintenance?

So Process Cat finally recommended that they check the thing that’s usually the culprit when you’ve checked all the other things.

The Surprisingly Common Cause of Process Variability: Environmental Factors

Yes, PCat and Rhonda were right to check their technique, materials, and equipment first. But when you’ve checked all those and still haven’t found the answer, it’s usually something in the environment.

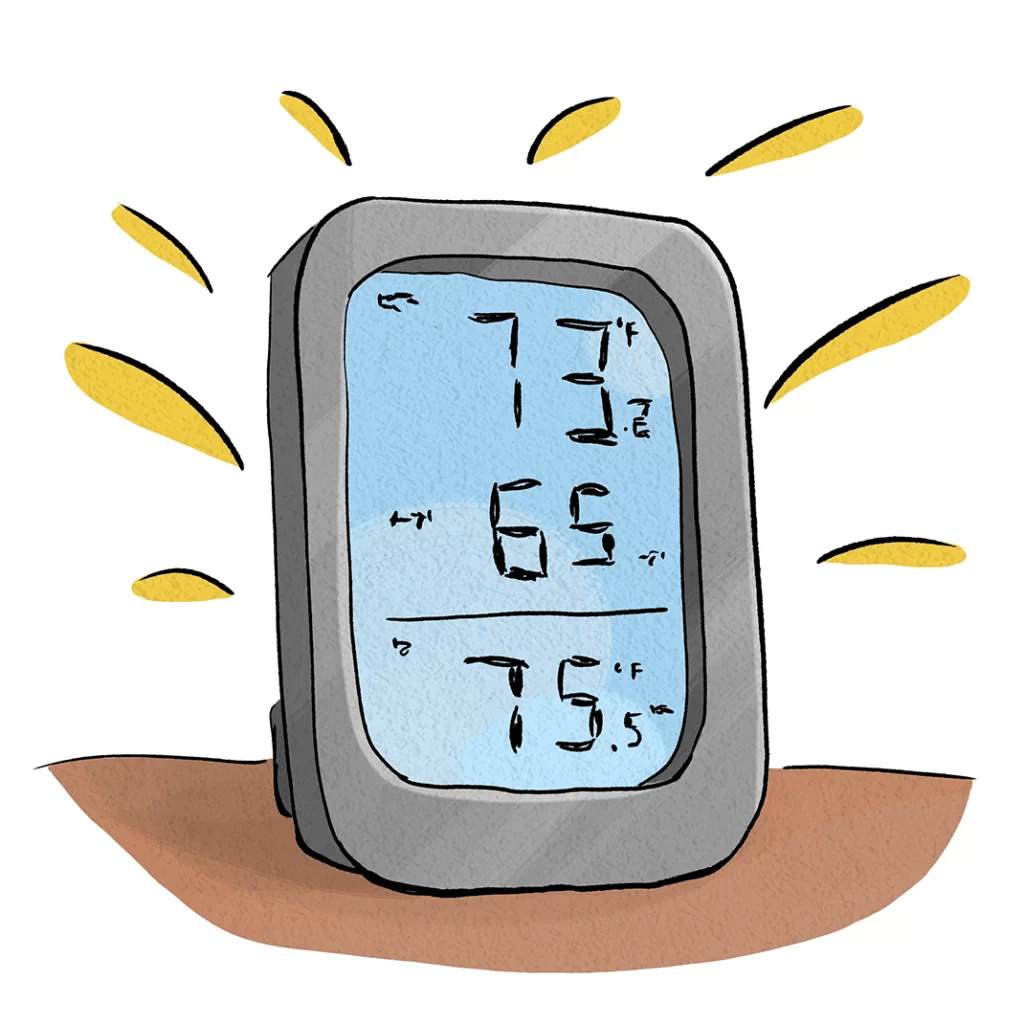

So Process Cat loaned Rhonda…

A hygrometer-thermometer!

A hygrometer-thermometer!A hygrometer, as you may know, is a device that measures ambient humidity. A thermometer, as I really hope you know, measures temperature.

And it was the hygrometer

Yup, the humidity. When Rhonda and Process Cat looked back through her records, they saw that ambient humidity correlated with the variability in her coasters.

What Rhonda did with that information is a story for the next article. But in the meantime..

Weekly Challenge:

If you have unexplained variability in your process, do a systematic review like Rhonda did! And come back next time to learn what you can actually do about that variability.