You don’t care about traceability in manufacturing!

Because as a small manufacturer (or Maker or Entrepreneur or whatever you call yourself!) you’re busy enough making good products and getting people to buy them.

But (and of course, there’s a but!) that’s something you may want to change. See, traceability (as it applies in manufacturing) means keeping good records of your parts as they make their way through your production line from raw materials to finished products.

And the advantage of THAT is that whenever you encounter a defective or problematic product, you’ll be able to pinpoint the cause immediately – saving you time, money, and headaches.

Princess Capybara didn’t know this at first…

If you’re a regular PCat reader, you know that Princess Capybara is a serial entrepreneur who recently branched out into purchasing an existing business!

The business made a premium skincare product derived from leaves. And at first, things were going great – the product practically sold itself, and she’d implemented some improvements in the schedule that greatly increased her profits.

But one day there was a problem!

There was one bottle, and then another, that…

Yeah. It was bad. Luckily for Princess Capybara, the previous owner had already implemented systems for…

Traceability!

See, the previous owner of the company had been a serial entrepreneur himself, and experience had taught him the importance of keeping good records.

So Princess Capybara looked through the records for the “bad” batch. She noted the batch numbers of the ingredients, the employee’s badge number, and whether anything unusual happened in the process.

The first thing she checked was the bottles of all the component chemicals that were used in the “bad” paint batch for anything unusual: were any of the chemicals expired? Were there any new bottles that might have arrived “bad” from the supplier?

Then she checked the employee badge number. If you’ve read about The Fundamental Attributional Error, you’ll see why it’s a common mistake to assume that any manufacturing problems are ALWAYS due to the person involved and not the environment or the reagents. So don’t do that! But, it is definitely a possibility that the person has something to do with the problem. (Particularly if it’s someone new.)

What Next?

In this case, it was the experienced and well-trained James. Of course, anyone could make a mistake, but it’s less likely to be due to a training issue when it’s an experienced employee versus a brand-new one.

In combing through the rest of the records, Princess Capybara notices from the timesheet that a longer time than normal passed between steps 4 and 5 of the process. What could be the cause of that?

She asked James to think back to that day, looking back at his calendar if necessary, and try to remember what had happened.

It turned out that on that day, James had had to leave the floor for an hour or so until the fire alarm issue was resolved.

So Princess Capybara double-checked the work instructions and saw that there was no mention of how long the serum could sit between steps 4 and 5 of the process. Interesting: it’s something that had never come up before!

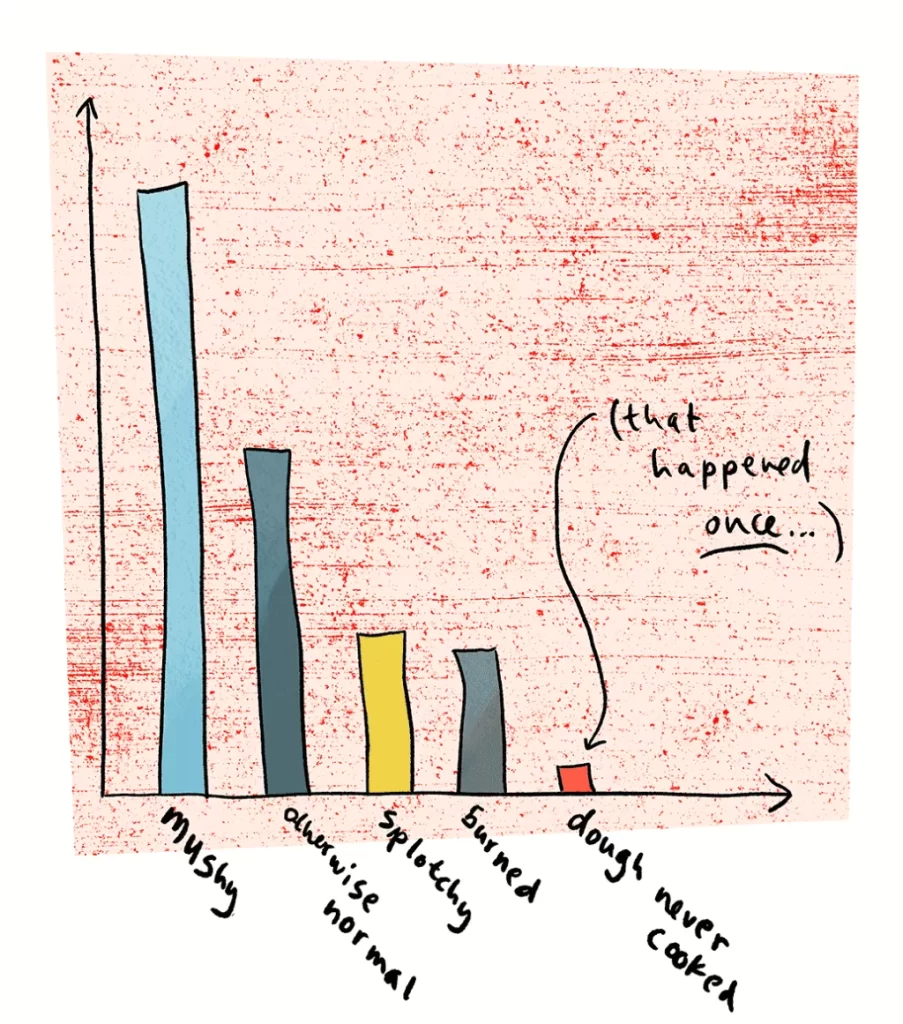

Next, Princess Capybara instructed James to do some experiments to test what happens when the serum sits for varying amounts of time between steps 4 and 5. And they found that after sitting for about 35-40 minutes at that stage, the resulting product would SMELL.

So they simply modified the work instructions to say that product could only sit 30 minutes at that stage (to be on the safe side) and the problem was solved!!!

Weekly challenge:

Do you have traceability measures in place for your processes? If so, great! If not, can you think of any mysterious problems that you might be able to solve by implementing some?