Yes, you do need to put some thought into your manufacturing schedule! Because small changes can make a big difference in your line’s productivity. But you don’t need to stress about it. We got you 😉

Princess Capybara didn’t realize this at first…

If you’re a regular PCat reader, you know that Princess Capybara is a serial entrepreneur. Her first business was a biotech company that she started with some of her classmates from grad school.

And after they cashed out of that, she started a passion project, making and selling things that she molds from concrete in her garage.

But recently, Princess Capybara had started to miss doing more of the real business-y things she learned in her previous career.

Ok, not nothing. But she had been itching for a new investment opportunity! Luckily, one day she was strolling through a local crafts market and something caught her eye…

The product was great, and as she learned chatting with the owner, the business was for sale! The owner was also a serial entrepreneur, but he was at a different phase in his career. Specifically? He had promised his wife that this was his last company and once he sold it they could retire to Mallorca.

Now, Princess Capybara was smart enough not to buy the business without making sure it was well-run and had solid financials. But she also made sure to choose a place where she could make improvements to the profitability!

And, based on her experience with manufacturing bottlenecks, Princess Capybara knew that she could make the business a lot more profitable by simply adjusting the manufacturing schedule!

Specifically, she had learned about something called Constraint Theory. Constraint theory basically asks, what is the biggest constraint on a business’s ability to make money? In Princess Capybara’s concrete molding business, the biggest constraint is her time. But in many manufacturing plants (including the one she just bought!) the constraint is that it’s very expensive to buy the industrial equipment used to manufacture the product.

The gentleman who started the leaf-derived skin serum business had purchased a large industrial extractor that gets the beneficial liquid out of the leaves without damaging the most important chemical in the process. This allowed him (and now her!) to make a superior product and charge more than the competitors.

Of course, this extractor was a huge capital investment! The previous owner had spent a few hundred thousand dollars to purchase the extractor and another hundred thousand to make all the necessary modifications to the building and set up the waste lines. And being a good businessman, he had factored these expenses into the cost when he sold the business!

So Princess Capybara better make sure she makes good use of that extractor!

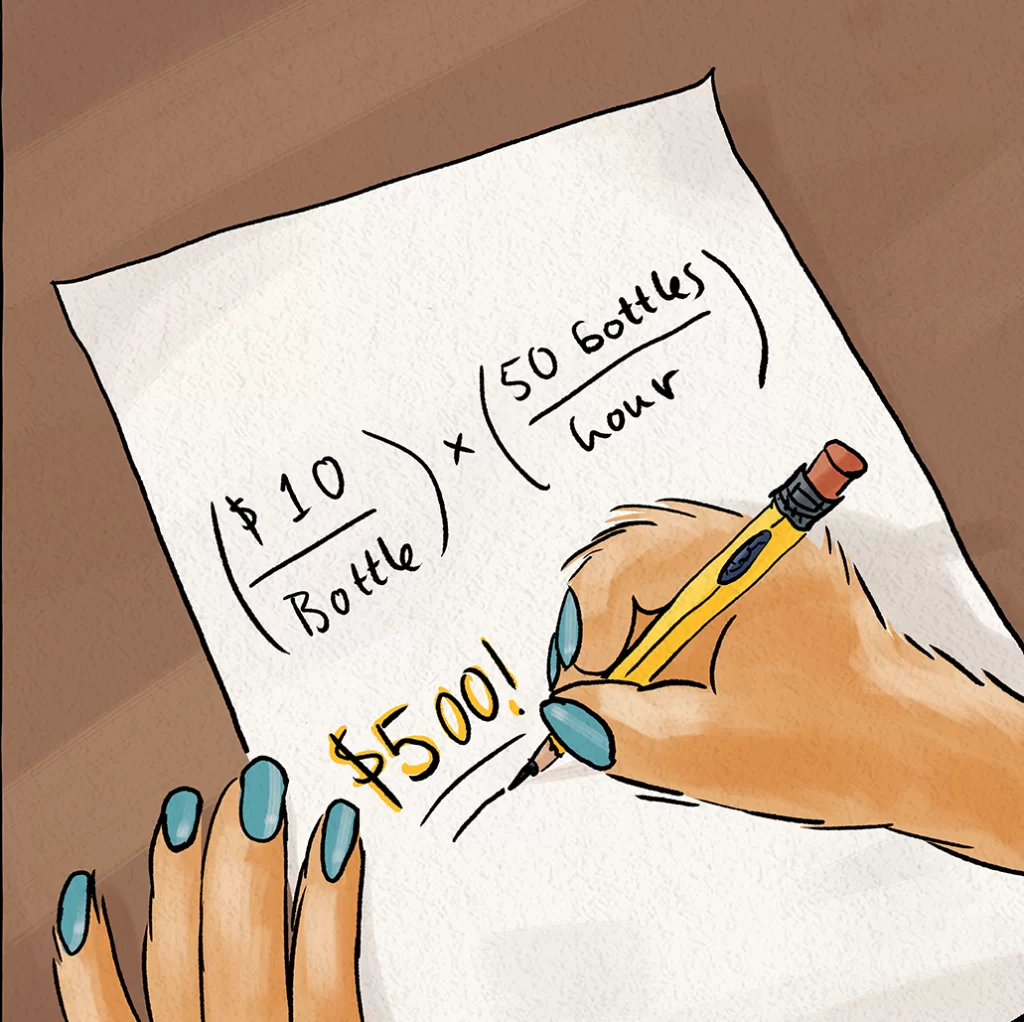

She did some quick calculations and figured out that for every hour the machine was running*, she stood to make…

She’s easily able to hire employees to run the extractor for much less than $500 per hour, even for nights and weekends. So, to make the most money, she should keep the equipment running as close to 24/7 as possible!

Weekly Challenge:

First, think about whether implementing a 24-hour manufacturing schedule (or getting closer to it!) could benefit you.

Extra credit: have you ever seen a manufacturing plant that DIDN’T operate 24/7? (There are plenty!) What do you think or know to be some of the reasons a plant would choose NOT to use a 24/7 manufacturing schedule?

*For this example, that $10 per bottle is her net profit after factoring in everything – the leaves, the marketing, wear and tear on the equipment, and all other expenses – except labor.