Everyone knows that having the right amount of inventory is crucial for small businesses.

But did you also know that there are different types of inventory???

Rhonda didn’t…

If you’re a regular PCat reader, you know that Rhonda is a retired nurse who now runs a small business selling wooden items that she makes in her garage workshop.

Anyway, she realized last time that if she was going to get serious about her business, she also needed to get serious about inventory management! So she asked her friend Process Cat for advice. Step 1 was breaking down the different types and functions of inventory. Luckily, once she thought about it, she was already familiar with all of them on an intuitive level 🙂

Work-in-Progress Inventory

Work-in-Progress Inventory is arguably an intermediate stage between raw materials (supplies) and actual inventory (finished beer mugs.) Rhonda always makes sure to have some reserves at every stage of the production process in case there’s a delay at one station, such as milling or painting.

Raw Materials Inventory

If you live in the US, you’ll be familiar with stores like Costco and Sam’s Club. Sometimes it’s more cost-effective to buy in bulk! And that can be another reason for keeping inventory.

Rhonda, for example, often chooses to buy the larger can of varnish from her local paint store even though she doesn’t need the entire thing today. The reason is that the cost of her total materials is lower when she does it this way, versus buying the smallest possible can to minimize her inventory…

Safety Stock

“Safety Stock” is a fancy way of saying “having some stuff on hand so you don’t run out.”

In business, this usually means having extra finished goods to sell. Because demand is never 100% predictable and it’s usually* better to have a little more product than you think you’ll need because it’s better to have enough for everyone who wants to buy.

But when talking to Rhonda, Process Cat shares an example from his personal life:

Because who would want to risk running out of that?

Pipeline Stock

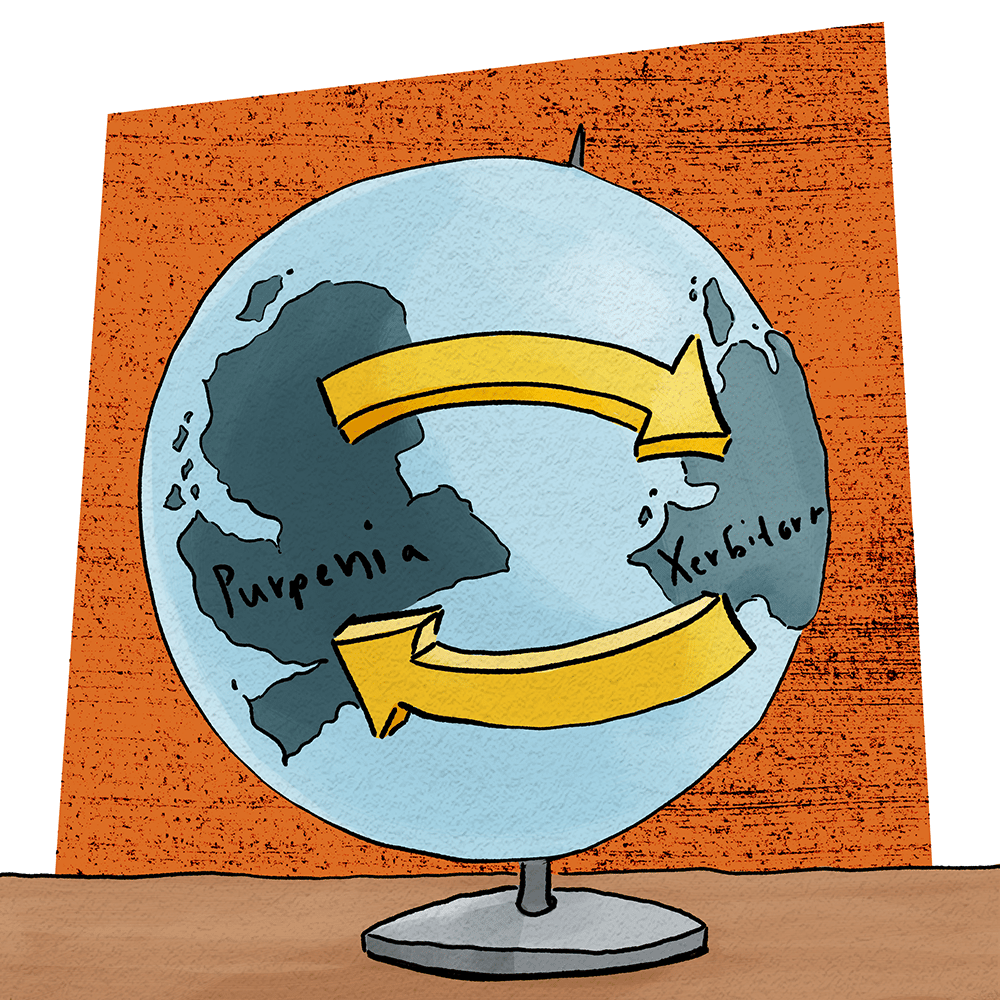

This will depend on your business model; specifically on what you’ve chosen to do for distribution. But the basic idea is, if you want to have a product available for people who want to buy it… you’ll also need to have some in transit.

Rhonda, for example, sells her beer mugs through a few different channels. You can buy Gnome-Shaped-Beer-Mugs in person, but you can also buy them from retail stores, or from her website, for which she uses a 3rd-party distribution partner**

Weekly Challenge:

If you haven’t, you really need to read the last article about the double-edged sword that is inventory! After that, use this week’s categories to help inform your thinking about which types of inventory you might want to increase or decrease. And in the next article, we’ll learn how to predict the right amount of inventory!

*As mentioned in our last article, there are valid exceptions, such as made-to-order products or using authentic scarcity as a marketing strategy. For the purposes of this discussion, we’re assuming you want to avoid having willing customers with nothing to sell them!

**Like Fulfilment by Amazon or FedEx Fulfillment.