If you’re scaling up your production, you know that your manufacturing bottleneck is important. You know that the bottleneck is the station or piece of equipment with the lowest throughput. (If you don’t? Start with this article and then come back 🙂

But did you ever stop to think about why finding your manufacturing bottleneck is so important?

Rhonda, Princess Capybara, and Gary didn’t…

If you’re a regular PCat reader, you know that Rhonda, Princess Capybara, and Gary are 3 friends who run their own small making/manufacturing businesses and regularly seek out help from their friend Process Cat. If you’ve been following the latest story, you also know that they decided to surprise Process Cat by filling his apartment with an army of figurines of himself on his birthday.

So yeah, it’s going to be great. But first they need to make sure they’re going to be able to make enough figurines in time for his birthday!

Here’s where manufacturing bottlenecks come in

When you’re striving to make enough of your product fast enough (whether for a whimsical situation like our friends above or for a more “normal” scenario like you suddenly have more orders than you’re used to handling and don’t want to keep your customers waiting!), you need to start by finding your bottleneck.

Everyone is familiar with the word “bottleneck” in a business or government process sense, and there are countless pages out there for people who want to “prevent bottlenecking.”

But did you know that in a manufacturing sense, it’s actually good to have a bottleneck?

Let me explain

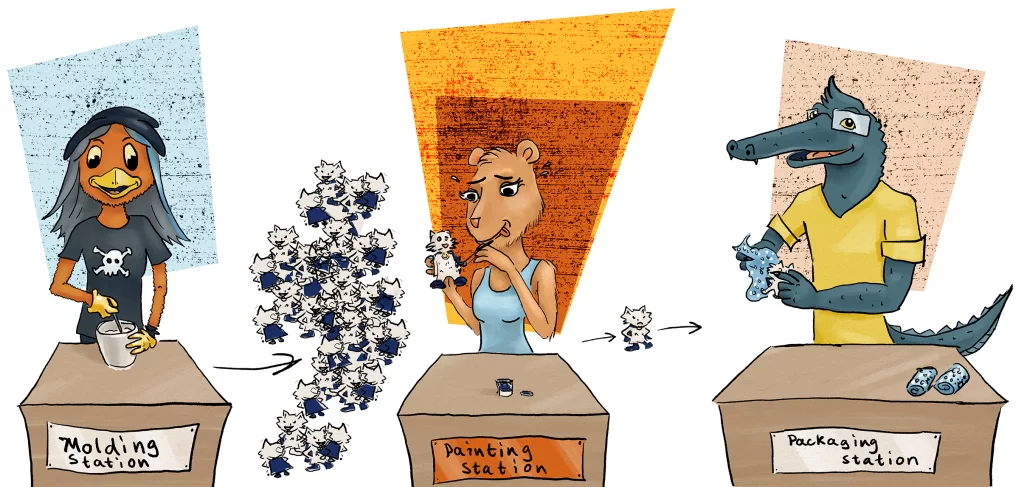

Process Cat’s friends came up with a system for making the figurines of their friend. First they mold the figurine, then they paint it, then they wrap it in bubble wrap to prevent it from getting damaged on the subway ride to PCat’s apartment.

But here’s the thing: each step doesn’t necessarily process the same number of figurines or take the same amount of time!

This will basically always be the case for manufacturing processes. Some steps happen fast and others are slow. The “slowest” one is your manufacturing bottleneck.

In our example case, let’s say the painting is the bottleneck.

Here’s the important thing about manufacturing bottlenecks

Notice the pile of unpainted figurines piling up after being molded but before Princess Capybara’s painting station.

More importantly, notice the LACK of figurines flowing from her station to Gary’s packing station.

And MOST importantly, notice that the total productivity (meaning total amount of figurines produced) isn’t at all affected by how fast Gary or Rhonda work.

…

Yes, you read that right.

No matter how many figurines Rhonda molds, and no matter how fast Gary packages the molds that come out of the painting station, the total number of finished figurines is always determined by how many per hour get through the manufacturing bottleneck!

So why don’t they just hire another painter?

Because this is a prank based on a loving friendship and they’re not really looking to hire random gig workers to help with it!

Ok, in a real-life scenario: if, as you’re scaling up, you discover that your bottleneck is a step whose capacity you can easily expand by hiring another worker and/or buying another inexpensive piece of equipment, you should absolutely do that! But often, you’ll reach a point where that’s not a viable option for one of two reasons:

- That particular step is highly skilled and you can’t easily hire another person to just double the output of that step.

- That step involves an expensive and/or space-consuming piece of equipment. It wouldn’t be easy to just buy another one!

Ok, can you just tell me the answer? What do I need to do about my manufacturing bottleneck?

Fine 😉

You need to keep the bottleneck working as much of the day as possible! If that bottleneck is a machine, that could mean it works 24/7 while workers relieve each others’ breaks so that the machine is never idle. If your bottleneck is a highly-trained person, well, eventually you’re going to need to train other people on the technique if you really want to scale. But in the meantime, you can minimize time that person spends on anything else. Delegate prep work and paperwork as much as possible.

In the end, your planning and preparation will pay off!

Weekly Challenge

Find your manufacturing bottleneck if you haven’t. If you have? Figure out how you can keep it fed! (Either way, come back next time to learn more about production scale-up.)

Oh, and in case you’re still wondering why I said it’s “good” to have a bottleneck in a manufacturing business? That’s because if your manufacturing process has a noticeable bottleneck, that means your marketing efforts are working well enough to sell everything you make. Which is good 🙂