When you’re having trouble producing your product fast enough, that’s a great problem to have! It means people like your product and you’re doing a good job of getting the word out about it with your marketing efforts.

But it’s still a problem you need to address!

In this article we briefly touched on the idea of Opportunity Cost: basically, if you have people who want to buy your product and you don’t have any product for them to buy, you are throwing away money! In this case, the calculation is not as grim as it was in that article. Since you’re not making the product, your “official” loss is only the profit you would have made by selling the product. But, if you’re a new company, you’re also hurting your reputation. You appear unprofessional; also, prospective customers may not be patient enough to wait for your product to become available and you miss the opportunity to impress them and make a lifelong customer!

Process Cat’s friends had a slightly different reason for wanting to scale up their production speed…

If you read the last article, you know that Process Cat’s friends decided to surprise him for his birthday by making an army of plastic figurines of himself! They chose a method called resin casting to make the figurines.

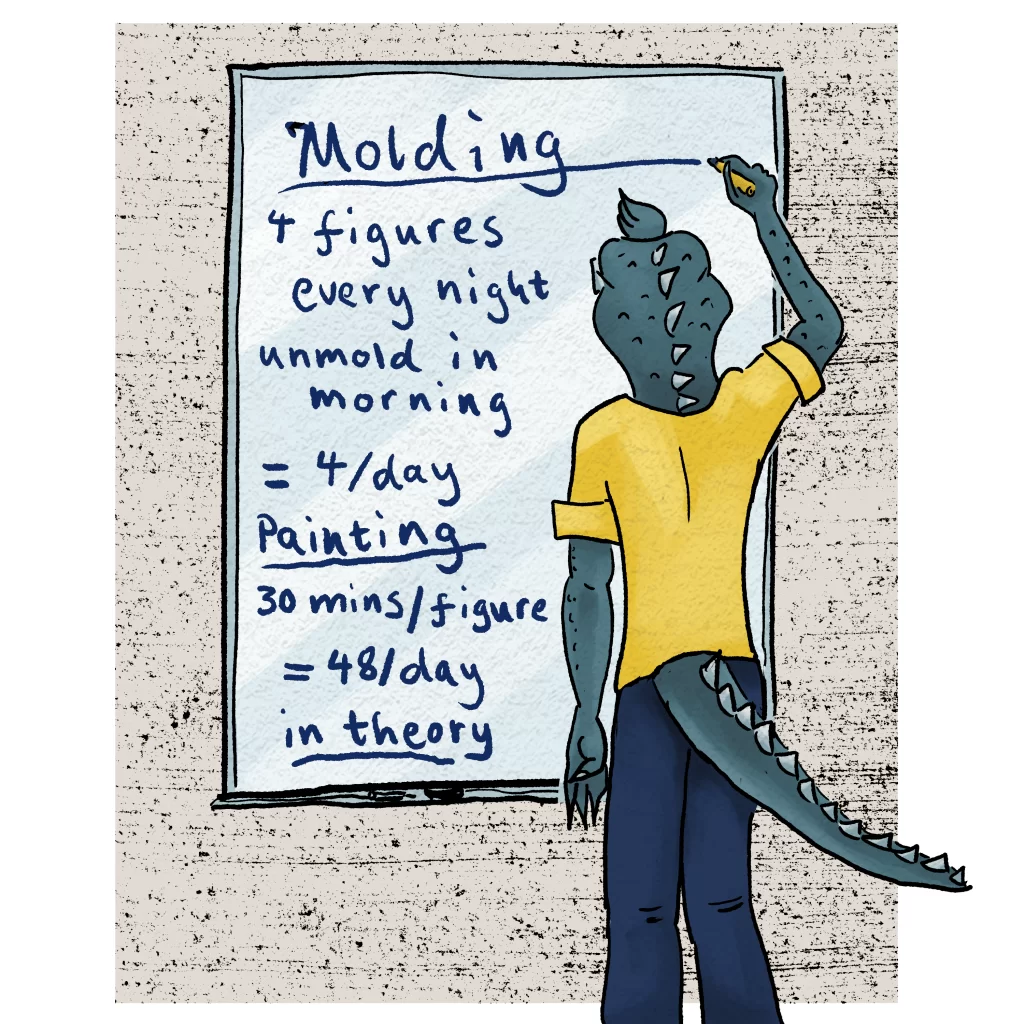

The problem is, Process Cat’s birthday is fast approaching and they’re not sure if they’ll get the figurines done in time! So they decided to go through and determine what was their bottleneck step. As it happened, their process really only had 2 steps:

The bottleneck is whatever step is the lowest throughput, meaning the one that produces the fewest number of parts per day (or per hour or whatever). Often it will actually be obvious by which step has a queue of parts waiting to be processed, and often the NEXT step in the process will be “waiting” for parts coming FROM the bottleneck.

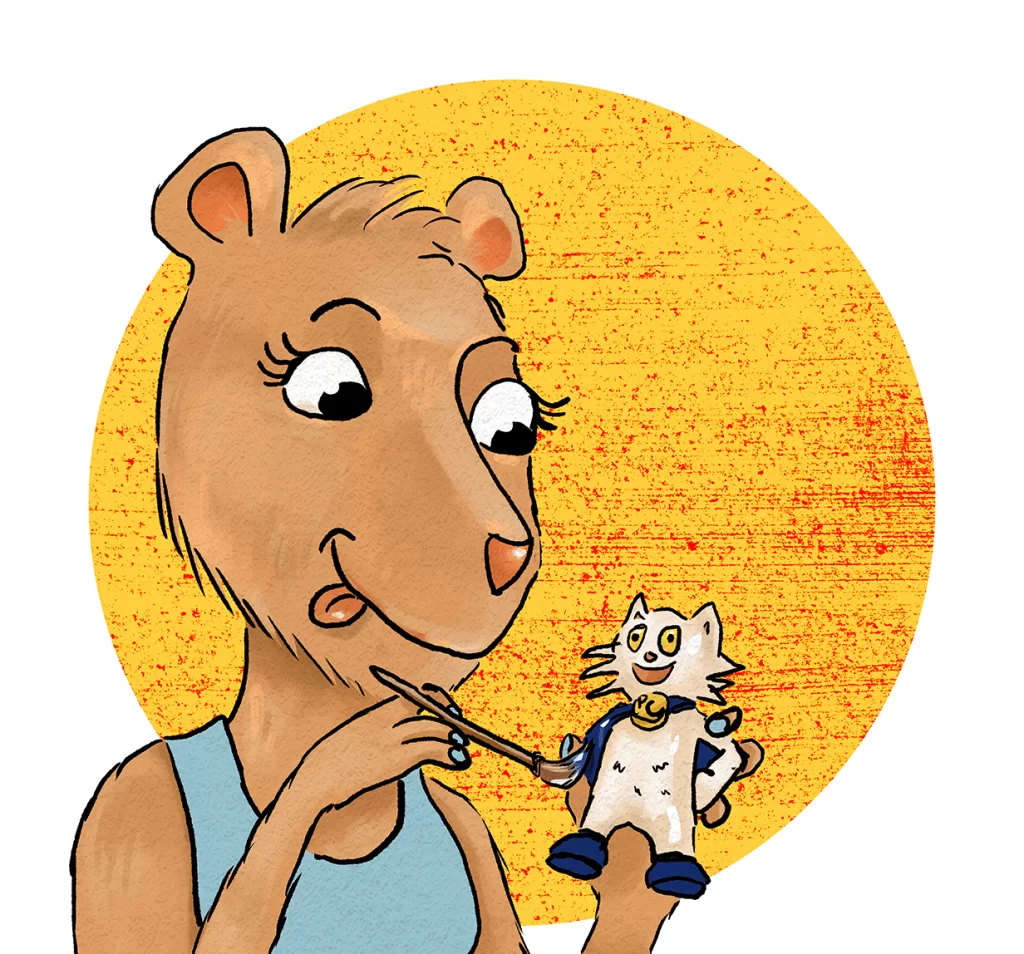

In Rhonda and Princess Capybara’s case, they saw easily that the molding step was their bottleneck.

(If your process is more complex, you can also do actual calculations. This can be done by having your employees (or yourself!) track how many parts get through each step of the process in how much time.)

Now the question became, did they actually have enough capacity on that bottleneck to get all the figurines made in time? If so, how could they make sure they actually got all the parts made? And if not, what could they do about it?

We’ll talk about how exactly they did all of that next time.

But long story short, they got the figurines done!

Weekly Challenge:

When you need to scale up your capacity, the first thing you need to do is identify your bottleneck. It may be simple as noticing which step has parts building up before it. Or you might want to do a more formal analysis. Come back next time to learn about manufacturing bottlenecks!