You know that “manufacturing” is really the same thing as “making something” in many ways. (If you don’t? Read about it in this article.)

But one of the biggest differences between making 1 vs. 100 vs. 100,00 vs. 1,000,000,000 of something is…

Different manufacturing technologies make sense at different scales!

This applies to all sorts of products made of all sorts of materials, but for today we’ll look at a fun example of making things out of plastic.

It all started with Process Cat’s birthday…

If you’re a regular PCat reader, you know that Process Cat is a wise, sagely superhero who enjoys drinking coffee and helping his friends with their manufacturing problems. And with his birthday coming up, Process Cat’s friends decided to throw him a surprise party complete with a very special touch.

Yes, the gang had decided to make miniature figurines of their friend Process Cat and place them all over his apartment as a fun surprise. Now the question turned to the best way to make the figurines. They considered a few popular technologies.

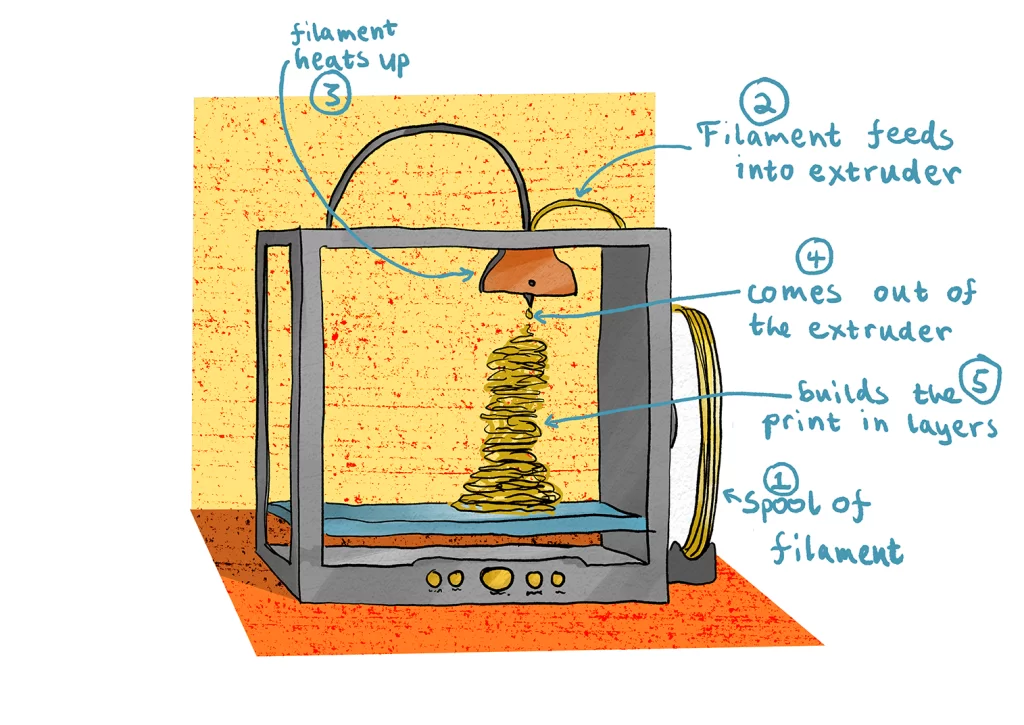

Manufacturing Technology 1: 3D Printing

Also called Additive Manufacturing, 3D printing is a great option for making plastic figurines! The figure is designed in 3D-modelling software (there are even some free ones available!) and then run through another software that allows the printer to make the item.

The biggest advantage of 3D printing is its low startup cost. Princess Capybara figures she can just teach herself how to use a 3D modeling software to make the design, then print it at her local Maker space.

But 3D printing does have some disadvantages for the project that they have in mind. See, 3D printing is slow. It will take hours to make each figurine! And it’s also expensive in the long run when you’re making a large quantity. They want a whole army of PCats, not just one!

So Gary suggests that they consider…

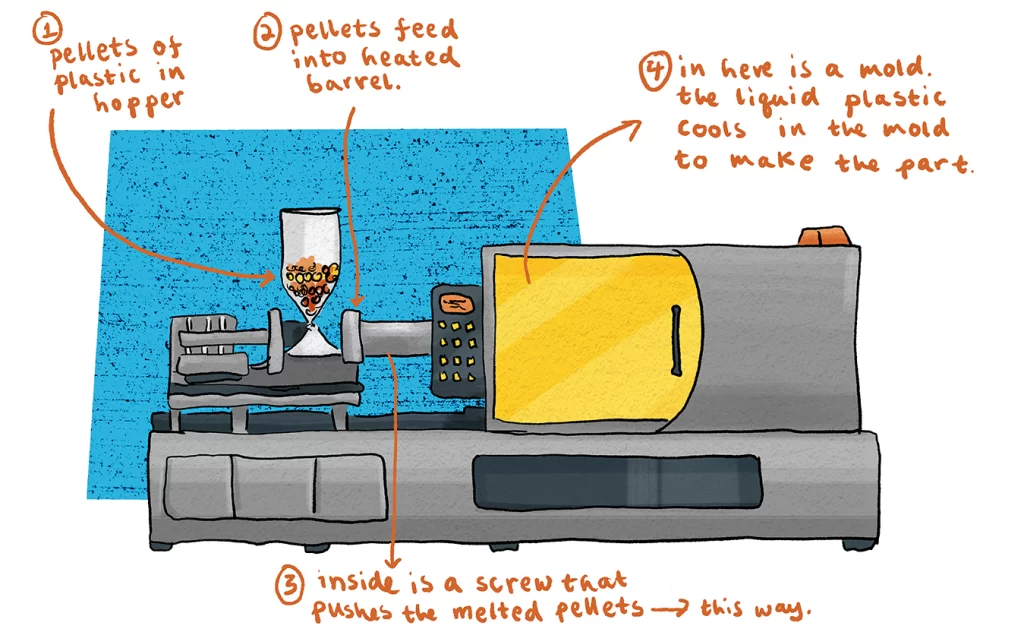

Manufacturing Technology 2: Injection-Molding

Injection molding is considered the “gold standard” for how to make small plastic parts at very large scales. (This is how many plastic toys you’d find in a toy store are made, for example.) Instead of tediously building the part in layers, the injection molding machine fills a mold with melted plastic as shown here:

And despite its association with very large-scale manufacturing, injection molding machines are also available at the workshop/benchtop scale. And luckily, their local Maker space has one! (Buying even a benchtop model would cost several thousand dollars, which is a lot for a prank…)

But there is still one main disadvantage to injection molding, and that’s the need for a mold. The molds require either purchasing a custom design from a metal machine shop, or 3D printing from a special, more expensive type of printer and resin. Either will be expensive and time-consuming. If they were making an army of 1000 or more figurines it might be worthwhile, but it’s a pretty high startup cost for their planned army of about 100.

This is why Rhonda suggests that they try…

Manufacturing Technology 3: Resin-Casting

Resin-casting is a popular bench-scale technology for making figurines in quantities between about 10-100.

For this method, they’ll still make ONE figurine by 3D printing. Then they’ll use that figurine to make a silicone mold. And then they can use the mold to make their army!

Weekly Challenge:

If you need to make anything out of plastic, consider whether one of these technologies is right for you! And if you make things out of wood or metal or textiles or whatever, look at whether there are similarly different technologies that work at different scales in your medium. (Hint: there are 😉

*Note: there are several types of 3D printers. The image in this article shows the most popular, Fused Deposition Modelling (FDM for short.)

Ps. Want to check out videos of some of these technologies? Here are a few that I happen to like: