You know that there are plenty of manufacturing technologies out there besides 3D printing, and that its reputation probably benefits at least a little bit from having such a cool name…

But you probably also realize that as an entrepreneur, small-scale manufacturer, (or creator, inventor, or whatever you call yourself), 3D printing legitimately is a very useful technology to know about.

When to use 3D Printing

3D Printing is often the best choice for rapid prototyping, which you’ll probably be doing a lot of as a startup/small business owner.

It’s also often one step in a setting up a manufacturing process that involves other technologies. One example is the resin-casting we did in this article.

And finally, there can actually be some reasons to 3D print items for sale. For two examples, it can be a selling point that makes the thing seem cool and futuristic for some products, and on a more practical note it allows for personal customization.

For these reasons, the gang decided that they wanted to learn more about the different types of 3D printing technologies…

If you’re a regular here at Zattatat, you know that the gang consists of Rhonda, a retired nurse who now makes and sells wooden coasters and beer mugs; Gary, an accountant who has a side business as a baker; and Princess Capybara, a young serial entrepreneur whose recent endeavors have included biotech, concrete molding, and skin serums.

They often ask for advice from their friend Process Cat, a manufacturing superhero who’s always happy to help. And recently, they asked PCat to give them a master class on manufacturing technologies.

Anyway, this week it was time to learn about the various types of 3D printing. Starting with…

Fused Deposition Modeling (FDM) 3D Printing

FDM is the type of 3D printing that will be most familiar to the average person. It’s the one with a spool of plastic filament that gets heated up and then squeezed out in a pattern determined by a digital file. It’s almost like the printer is “drawing” the object with a hot glue gun, as a terrible but probably understandable analogy :p

Anyway, in this article we’re actually not going to cover the technical side of FDM printing in much depth because it’s been covered here.

But there are some things we should mention about the relative strengths and weaknesses of FDM printing, and when it’s appropriate to use it.

The great thing about FDM is that it’s usually the most inexpensive type of 3D printing, both in terms of cost of the printer itself and in terms of per-unit materials cost. FDM printers can also be small, lightweight, and don’t create as much “mess” or require nasty chemical solvents, so it’s very well-suited to be the printer you keep in your home or office for quick-and-dirty prints such as the rapid prototyping we mentioned before.

FDM’s main downsides are: it produces parts with relatively bad mechanical properties due to, well, being basically drawn with hot glue to reuse that bad analogy. Also for the same reason it produces parts with characteristic ridges that some people find unattractive (think like the coil pots you made in the “pottery” section of your elementary school art class…) These can be smoothed out in post-processing, but that can be time-consuming.

So, that’s the gist of FDM. Moving right along, let’s talk about…

Stereolithography (SLA) 3D Printing

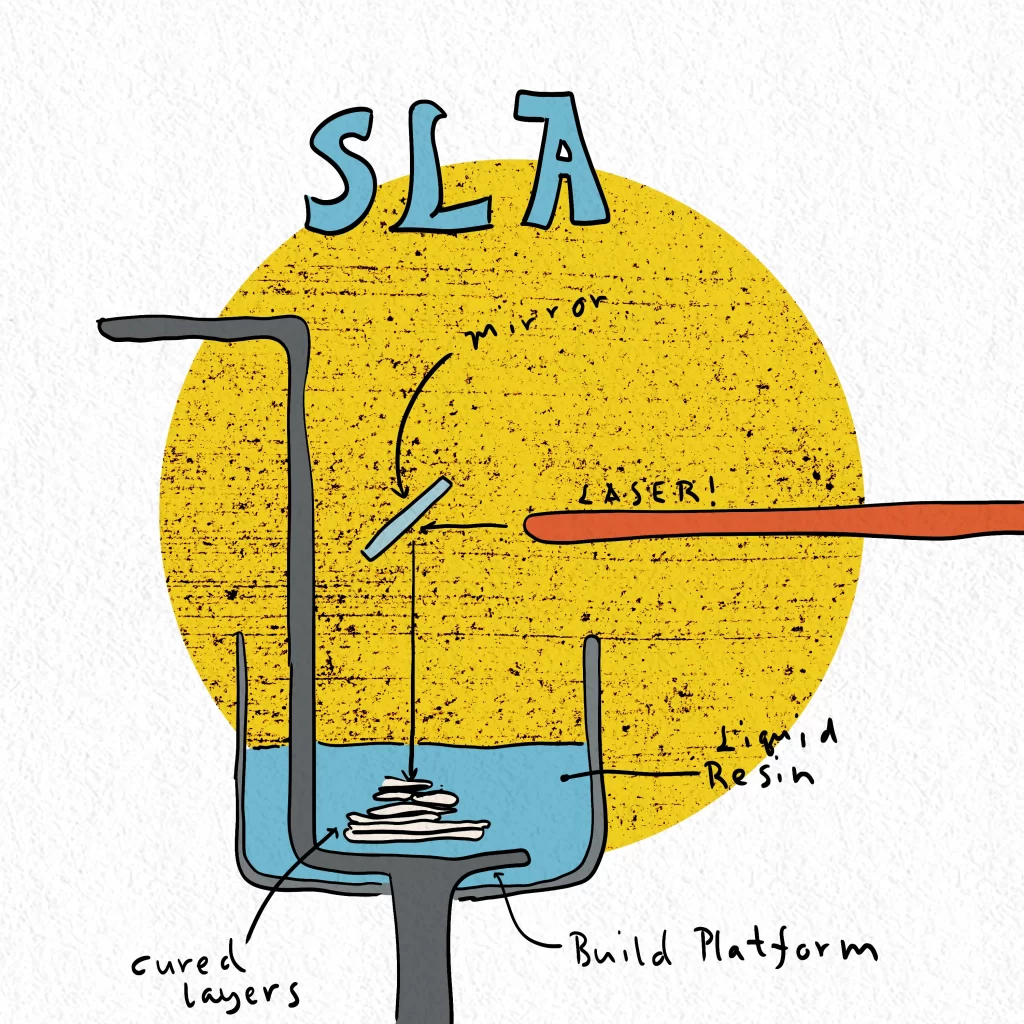

In SLA 3D printing, a vat of some type of curable resin is selectively exposed to a laser that cures the resin. The shape that is cured is, again, directed by a digital file. (Actually, that’s the case for all of the types of 3D printing and many if not most other modern manufacturing technologies.)

Anyway, here’s a general diagram of SLA 3D printing:

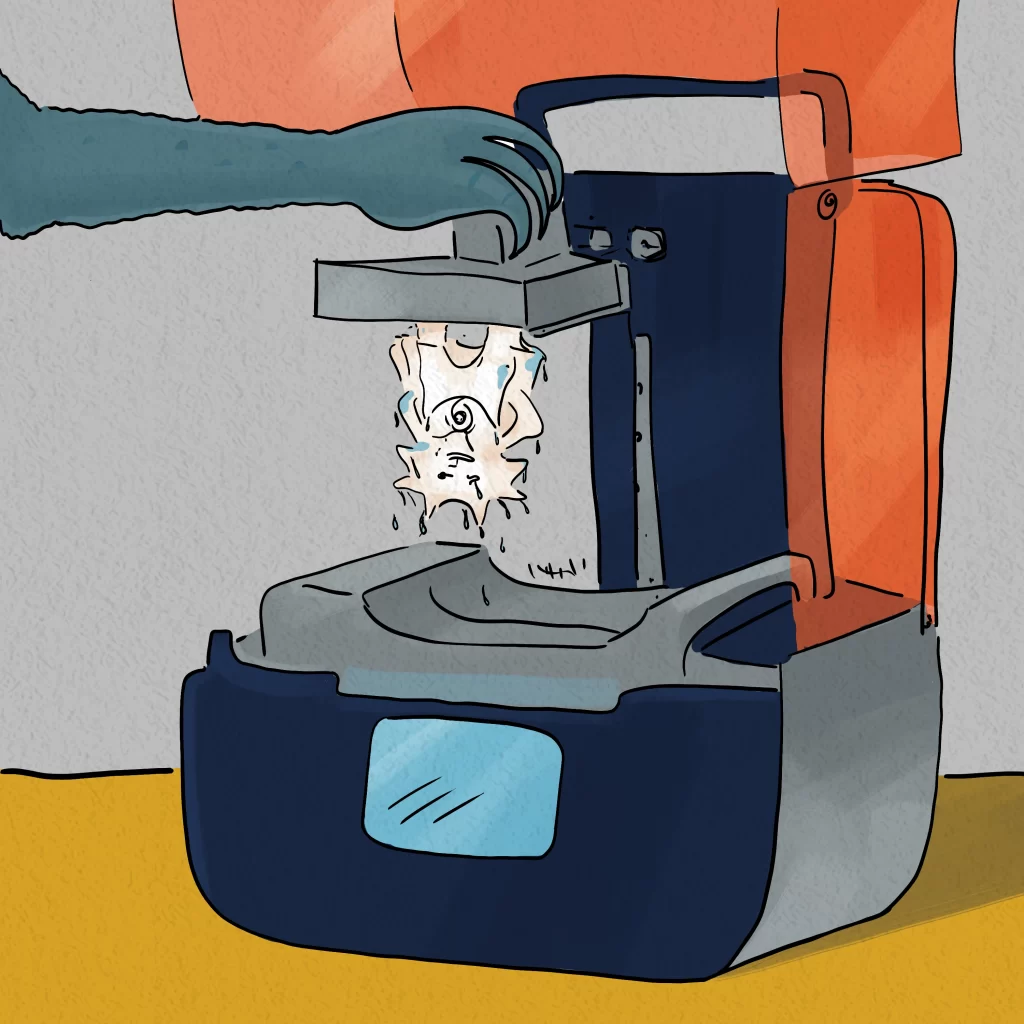

Here’s what a consumer/small business model of an SLA printer looks like in a more visual, less conceptual illustration. Note that in this SLA printer, the build platform is on the top instead of the bottom like it is in the diagram. That’s because SLA printers are…

Yeah, so the thing about resin is that it’s basically the consistency of honey, only made out of chemicals that you shouldn’t touch and that (in many cases) will cure into a solid when exposed to sunlight for more than a minute or two. And when the part is cured, as you can see in the picture, it’s covered in goop that needs to be cleaned off with solvents. So mess and smell are basically the downsides of SLA for home or office use. Another downside relative to FDM is price: both the upfront cost of the printer and the per-unit materials cost will tend to be higher for SLA printers than for FDM.

So why use SLA printers? Materials properties, for the main one. SLA-printed parts will tend to be much more sturdy than FDM parts even when made out of generic resin, simply because of the more robust way that they’re made. Also, there are commercially-available SLA resins that are specifically made from materials with various thermal, mechanical, and chemical properties that simply aren’t available for FDM printers. And, while SLA printers are more expensive than FDM printers, they’re still generally less expensive than…

Selective Laser Sintering (SLS) 3D Printers

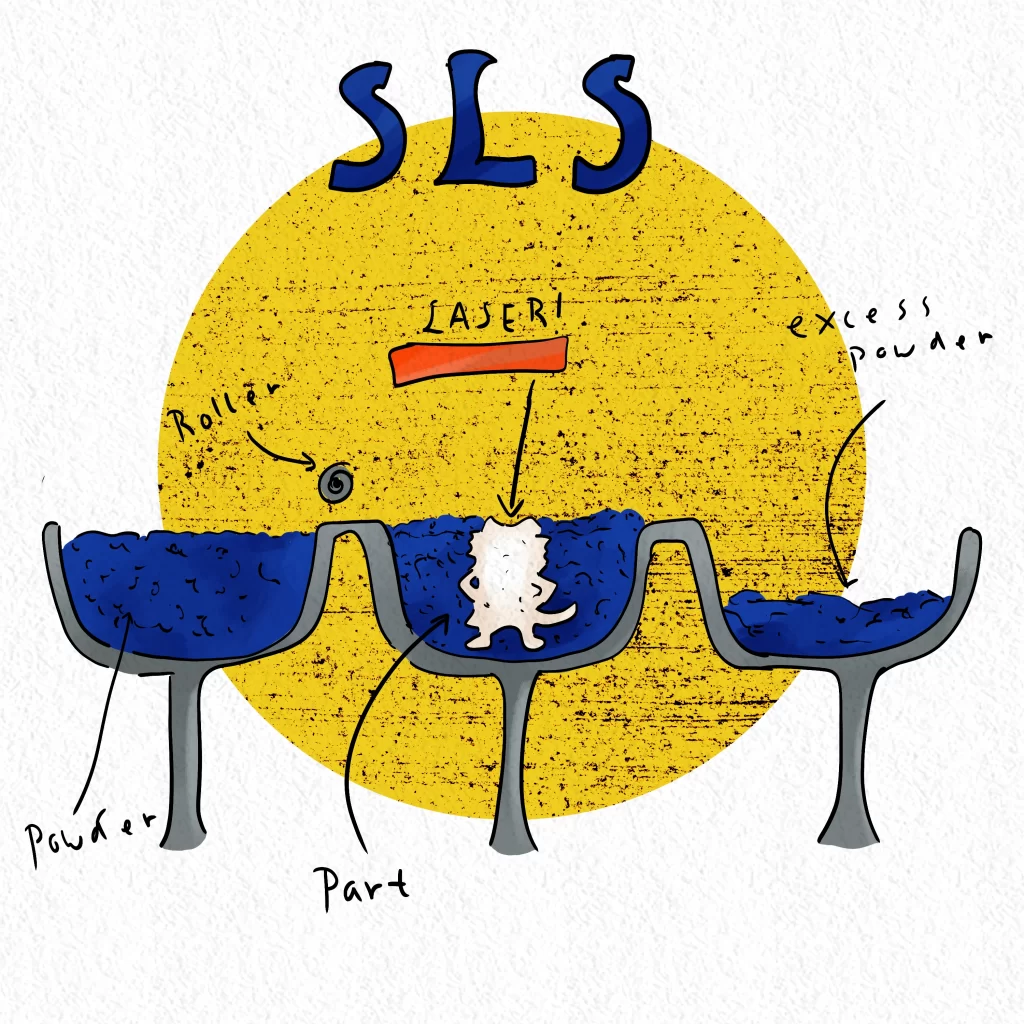

In SLS printing, small beads of material are sintered together by, again, a laser that is, again, being directed by a digital file.

Sintering is a process in which heat (from the laser, in this case) causes particles at the edge of each bead to move and intermingle such that the beads end up getting fused together to form a solid.

Note that sintering can occur significantly below the melting point for a given material, which is one advantage of SLS technology.

Some others are: no need for support structures. We didn’t mention this yet, but both FDM and SLA prints frequently require support. These are essentially “scaffolding” that is printed for the sole purpose of supporting the actual part while it is being built. Since SLS occurs in a bin full of powder, supports are unnecessary. That makes it a good choice for parts with complex geometries, where designing and then removing the supports would be difficult. SLS-printed parts also have even better mechanical properties than SLA parts, and have low per-unit materials costs.

The main disadvantages of SLS printing are high upfront costs (ie, SLS printers themselves are significantly more expensive than FDM or SLA), and fewer options for commercially-available build materials.

Weekly Challenge:

Are you in the market for a 3D printer? If so, run through the pros and cons of the ones we’ve discussed here and decide which might be best for you. (Ps. Don’t forget that if you only need a few parts printed, you might be better off renting time on a printer at a local Maker space or using the services of an online company to print your part!)