You might see this title and think, no, industrial automation isn’t for me! I make beaded curtain ties (or handmade knives, or pineapple-shaped pencil holders…) and I make them by hand!

Misconceptions about Industrial Automation

If you’re scared off by the word “industrial”?

Don’t be. For our purposes, we use the phrase “industrial automation” to mean automating a manufacturing process, as opposed to automating a non-physical process in a business, government, or nonprofit setting.

Beyond that?

Many people assume that there’s a sharp dichotomy between making things fully by hand and making things in a way that’s fully by machine, with virtually no human involvement at all.

Many people also assume that automating manual tasks is always bad for people – conjure an image of an army of evil robots coming to steal everyone’s jobs…

And finally, many people assume that industrial automation always means expensive robots and giant pieces of machinery housed in a large, smelly factory.

And automation certainly can be all of those things! But it doesn’t have to be. Believe it or not, the principles of automation can be useful even to a small Maker-style business.

What else can automation be?

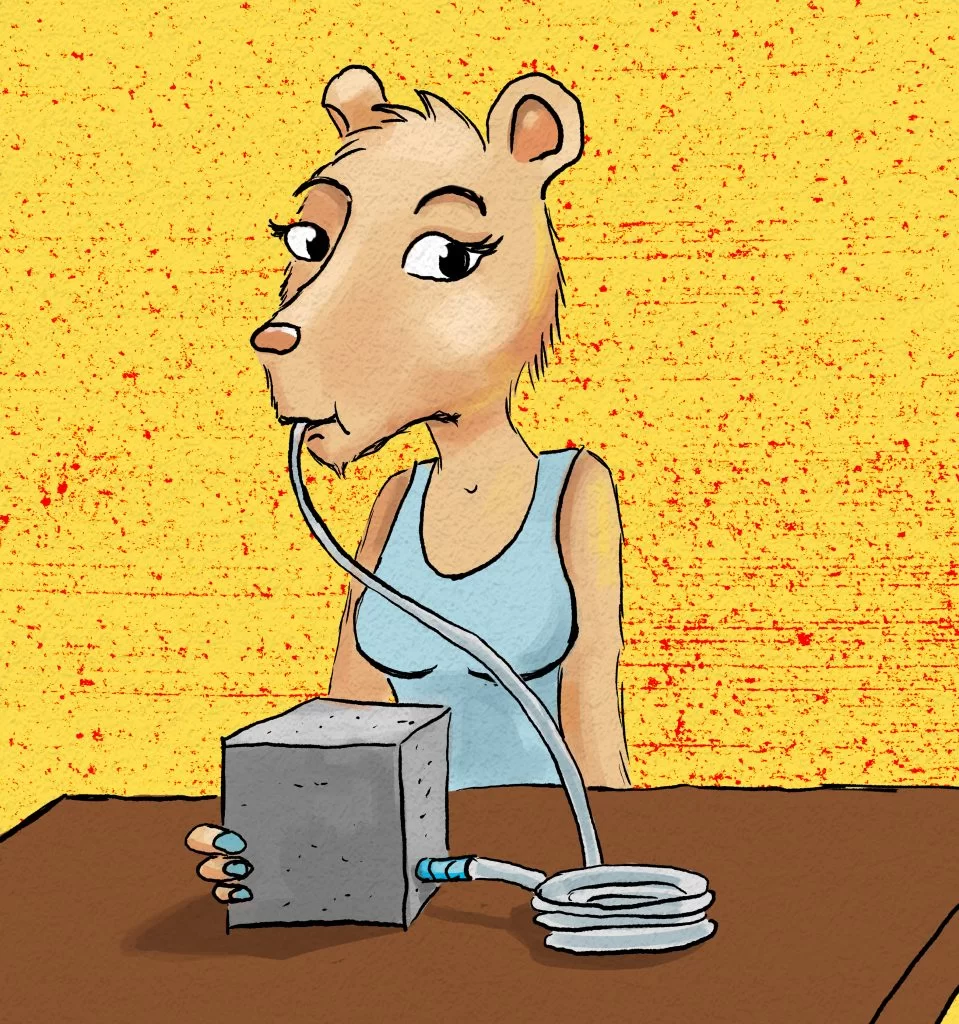

This is Princess Capybara

If you’re a regular PCat reader, you know that Princess Capybara molds things out of concrete in her workshop. Her star product was the Secret Wine GlassTM.

Recently, the Princess decided to add something a little cheaper and, um, more broadly-appealing to her product mix. See, only some people like drinking wine. (And even fewer like drinking wine through a hose!)

This turned out to be a great idea – coaster sales are really taking off! But there’s one problem….

Which brings us to the first reason you might want to think about automation: automate those tasks that are boring, repetitive, difficult or dangerous for people to do!

Yes, it’s true: there really are some jobs that people really won’t mind “losing” to robots…. particularly if there aren’t actually any people losing jobs. (In Princess Capybara’s case, she’s not firing anyone – she never had any employees to begin with!)

There are multiple reasons you might want to consider automation or at least implementing some of its principles. Here are a few: to improve quality, to decrease costs, to increase capacity, and (as mentioned) to avoid having human workers perform tasks that are boring, repetitive, difficult, or dangerous.

Weekly Challenge:

Look through your manufacturing/making processes with a fine-toothed comb. Are there some that you’d rather not have a person doing for one reason or another?

Come back next time and we’ll talk about how to actually go about automating some of your processes!