You have a small- or mid-sized manufacturing operation, and you’re ready to start automating it. Maybe you came to this idea on your own, maybe you read about it elsewhere, or maybe we here at Process Cat convinced you in the last article when we talked about how no operation is too small to start automating, or at least using some of the principles of automation.

But before you start automating your manual processes, there are a few things to consider.

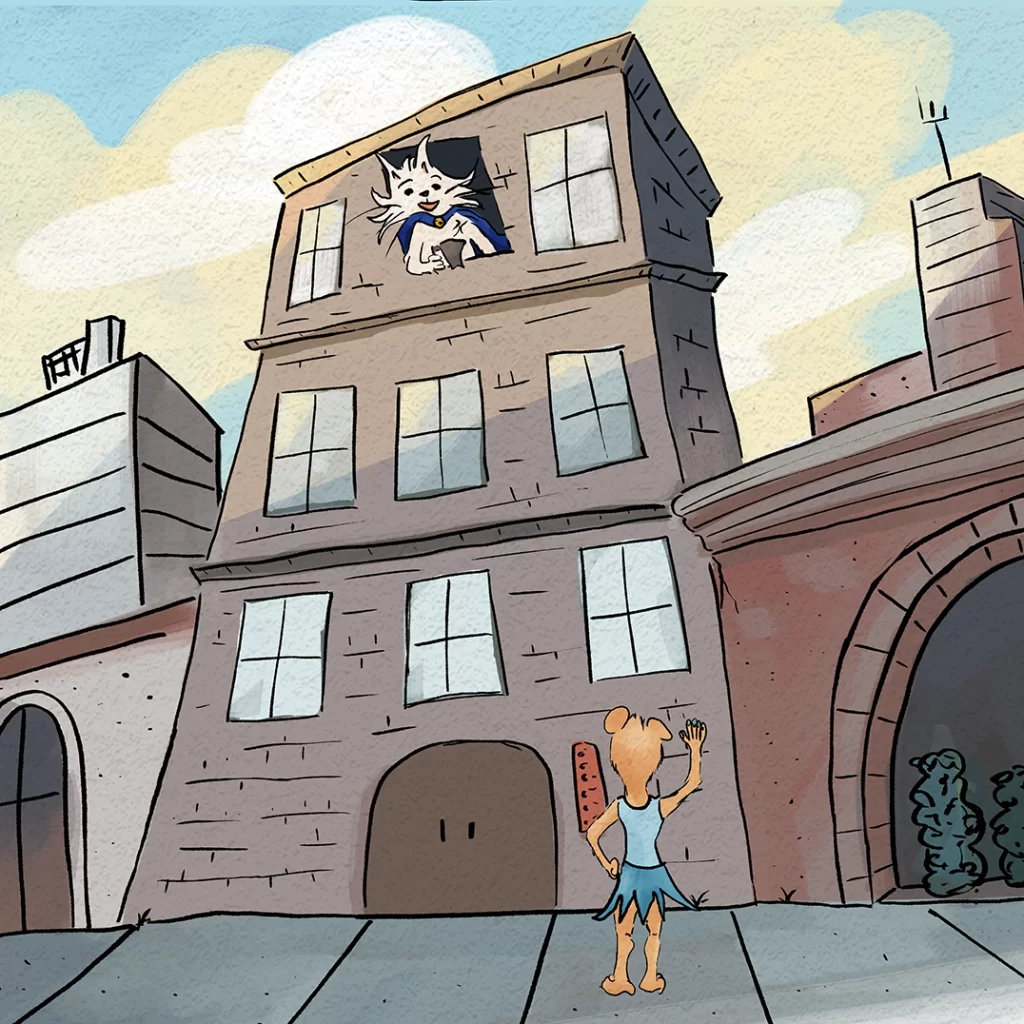

Princess Capybara got a little too swept up in the excitement of automation…

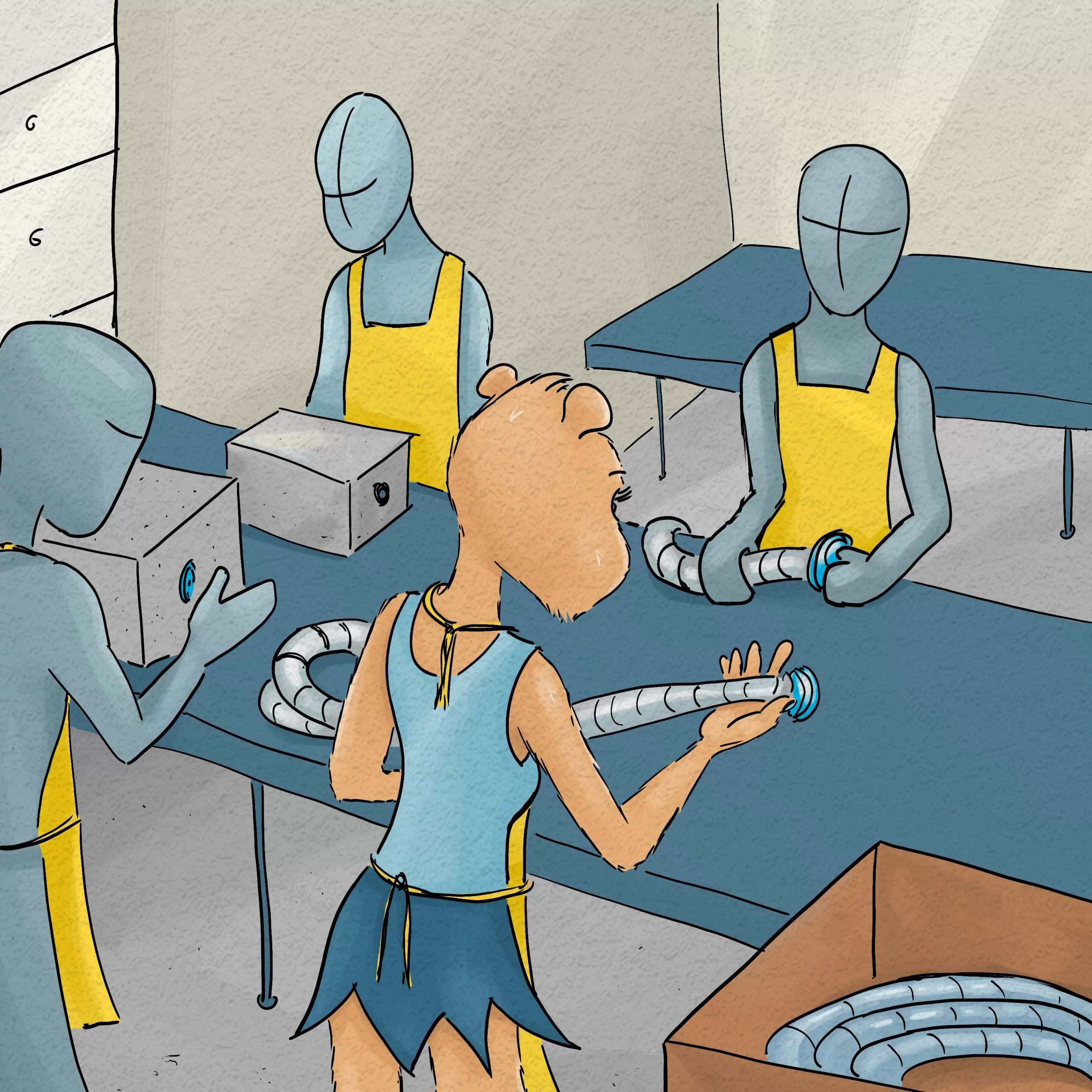

If you’re a regular PCat reader, you know that Princess Capybara runs a small business molding things out of concrete in her garage workshop.

Princess had the idea to automate her coaster-making process. So she raced over to her friend Process Cat for advice on how to do it!

And, of course, Process Cat obliged. He’s always happy to help his friends.

But as Princess Capybara paced around the room, talking excitedly about how she wanted to automate every aspect of her coaster-making system, Process Cat finally had to say….

Slow Down!!!!!

Let’s start with why.

See, it’s really easy to get caught up in the idea that every single thing should be automated. I mean, I get it, robots are objectively awesome.

But for real, you need to think about what are your business and/or lifestyle reasons for wanting to automate parts of your process. Is your primary objective to have better quality control? To eliminate a boring or dangerous task for yourself or your human employees? To save money by having fewer workers perform the same amount of work? Getting clear on your aims for automating will, well, make it a lot more likely you’ll achieve those aims.

In Princess Capybara’s case, her primary goal is to cut back on the time she spends on boring tasks so that she can focus on other parts of the coaster making and of running her business.

After why comes what

Once you’ve decided what you want to achieve with automation, the decision of what to automate will be easier. Now, mentally walk through your process and list out all the steps.

At this point just list them, not leaving anything out. But your mind may already start jumping ahead to the next step, which is looking at which parts of your process you most want to automate to achieve your goals…

And we’ll be talking about that next time!

Weekly Challenge:

Do consider automation but don’t get caught up in the idea that you have to automate everything in your process! Get clear on your reasons for wanting to automate. Then, get a jump on the next step by simply listing out the steps in your process 🙂