Why is Quality Control Needed?

You’ve probably heard that big manufacturing companies have quality controls. In this article, we’ll learn the somewhat surprising reason they’re needed. First, we need to back up and talk about variability. Did you know that EVERY process has inherent variability?

This probably makes some intuitive sense: think of making a batch of cookies. Some have more chocolate chips than others. You know that from cooking or at least eating them, right? You probably know it from your own business too. Rhonda sure does: she has a woodshop where she makes wooden coasters.

Why is each Piece Different?

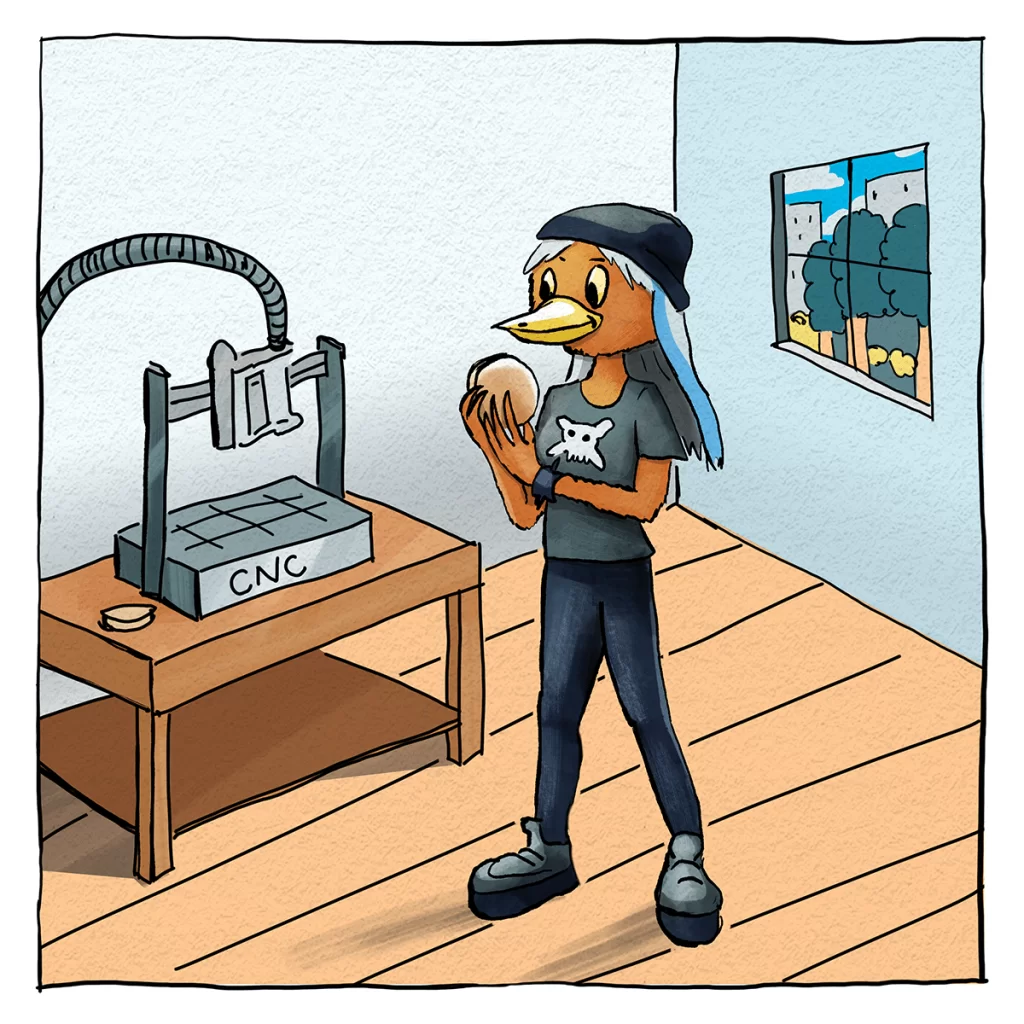

Rhonda uses a CNC machine now. But when she first started she cut out the coasters using a hand saw. When she switched to using the CNC, she thought that all the coasters would be identical just like the ones from a store. But they’re still not all identical.

Why is that? What Rhonda knew intuitively was that using the CNC instead of cutting by hand would reduce the variability in the process. (And she was right: the coasters are more uniform when cut by a computer-controlled instead of a person-controlled machine.)

But there are still other sources of variability, as in fact, there are in all processes! In her case: Variability in the material (plywood) can cause the cut to happen differently. Seasonal changes in the temperature and humidity can change how brittle or flexible the wood is and (again) cause the cut to happen differently. Even the machine itself isn’t perfectly rigid. It can move a little bit, which also…

Does This Only Affect Small Maker Businesses?

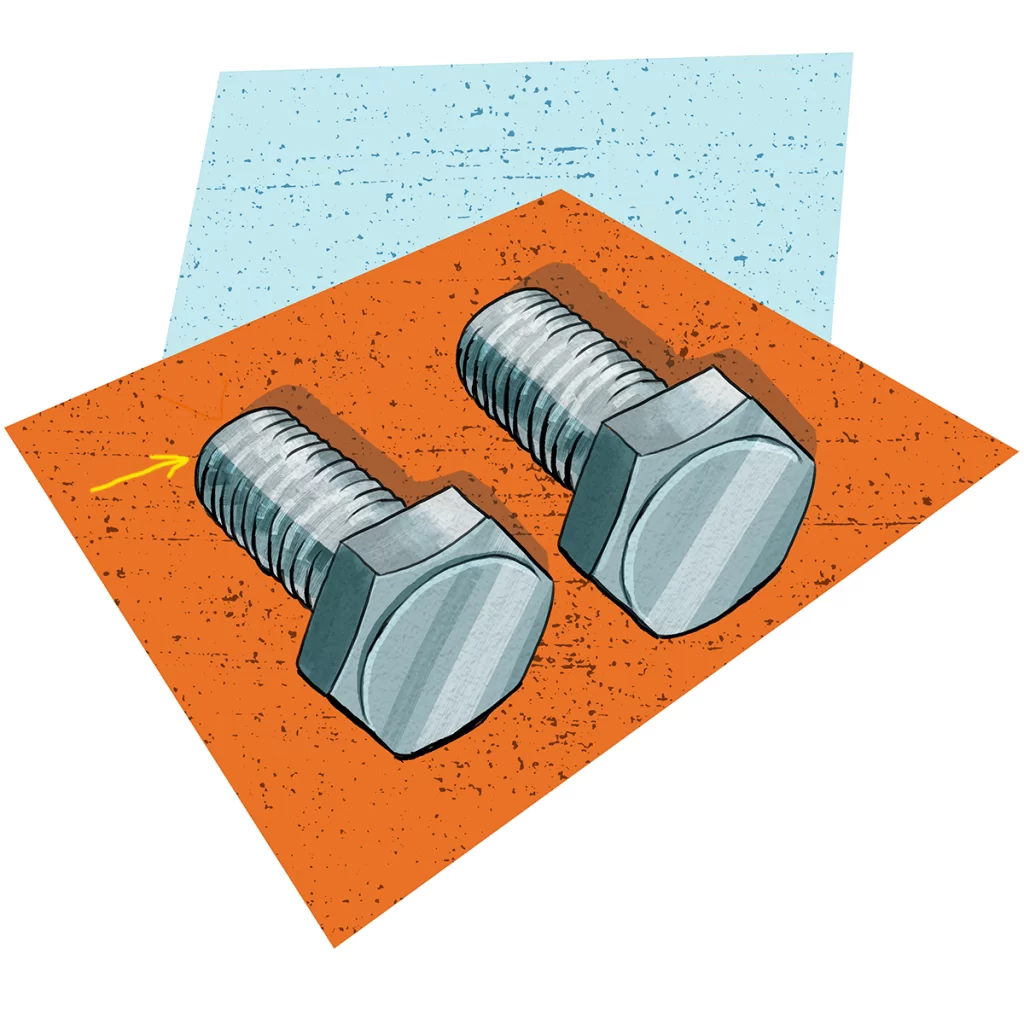

And believe it or not, this is the case for mass-produced items too! There is some amount of variability even in items you buy in a store. In Rhonda’s case, she’s noticed this with the nuts and bolts that she buys at her local hardware store.

Almost always they fit together as they should, but once in awhile, they don’t. More commonly they do, but some pairs seem to fit better than others. Why is that? Well, the bolts are also made by a manufacturing process. (If you’re curious, check out this video to see it!) And, just like with Rhonda’s process, it has some inherent variability too!

The Two-Pronged Strategy You Need

As with Rhonda’s coasters, not all of them are exactly the same! The reasons we tend to think of them as all being the same are because the manufacturer has implemented two strategies: Quality Controls and Quality Assurance. In our next post, we’ll look at what these are and how to implement them.

Weekly Challenge: Think about areas of variability in your own products, and in the products you buy. Did you ever stop to think about what causes them?