If you’re scaling up your Making or Manufacturing business, sooner or later you’ll want to perform a formal (ok, let’s get real, a semi-formal 😉 manufacturing capacity analysis.

Yes, I promise, it really is easier than you’re probably thinking.

Process Cat’s friends were able to figure it out…

If you’re a regular PCat reader, you know that Process Cat is a magical superhero who lives in New York, drinks coffee by the gallon, and loves nothing more than helping his friends solve their small-scale manufacturing problems. And if you’ve been following the latest story in particular, you know that his friends decided to surprise him by making an army of plastic figurines for his surprise party!

Just like you, they were concerned that their manufacturing capacity might not allow them to make all the figurines in time for Process Cat’s birthday!

Ok fine, you’re probably more concerned with making enough of your product to fulfill your Kickstarter campaign or to avoid having product out of stock following a big PR or advertising push. But stay with me.

Ok, so what is Manufacturing Capacity?

Glad you asked 😉 It means the amount of parts your equipment would be capable of making if it were staffed and running 100% of the time.*

Why do we calculate it that way? Because usually an expensive piece of equipment is the bottleneck in your manufacturing line. (If it’s something cheap? Just buy another one!!)

In general, it’s possible to add more employees or to pay your existing ones to work a little overtime, or even to step in and do some of the work yourself. But this will only solve your manufacturing capacity problem if your equipment actually has enough capacity!

Enter the manufacturing capacity analysis

You’re going to want to start by finding your bottleneck.

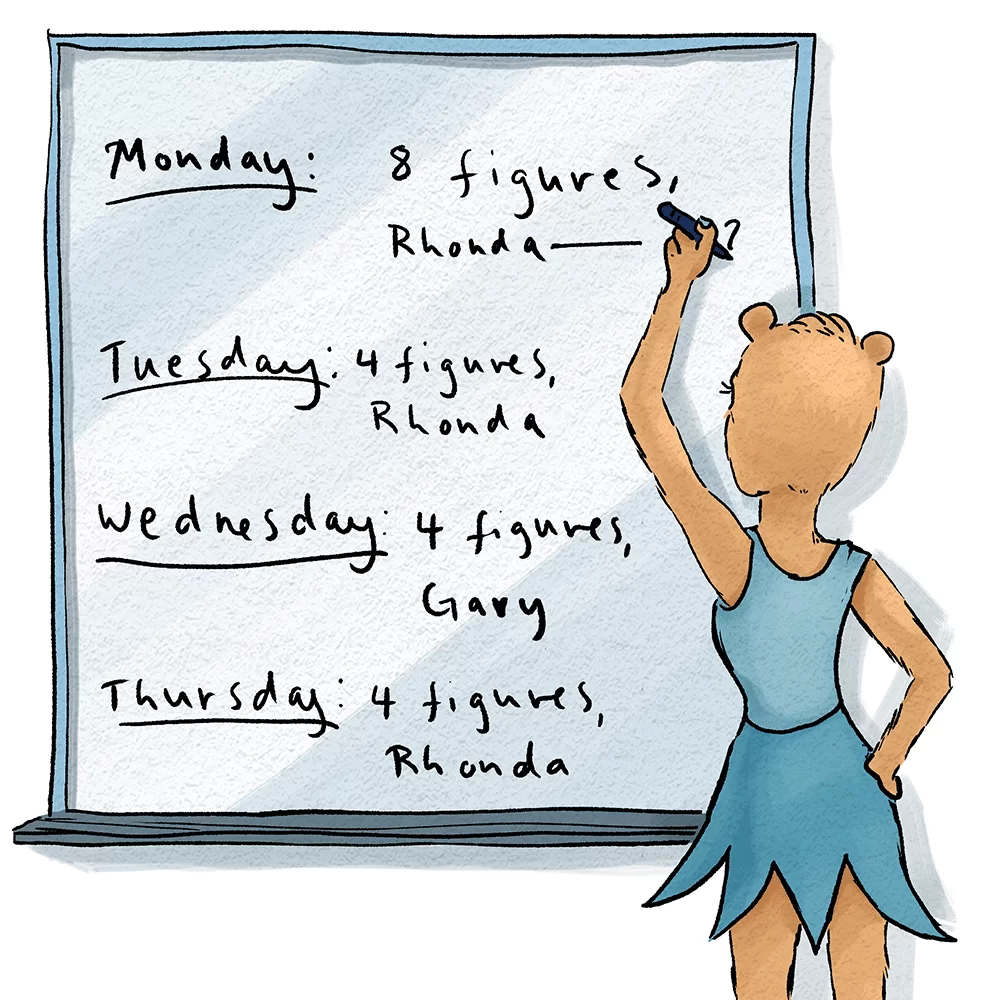

Gary, Rhonda, and Princess Capybara’s old bottleneck was painting. But, as paintbrushes are cheap, they got rid of that bottleneck and their new bottleneck is molding. They have 4 molds so normally they mold 4 figurines per day. They either load the molds at night and unmold in the morning, or the opposite, depending on everyone’s work schedule. So does their equipment have enough capacity?

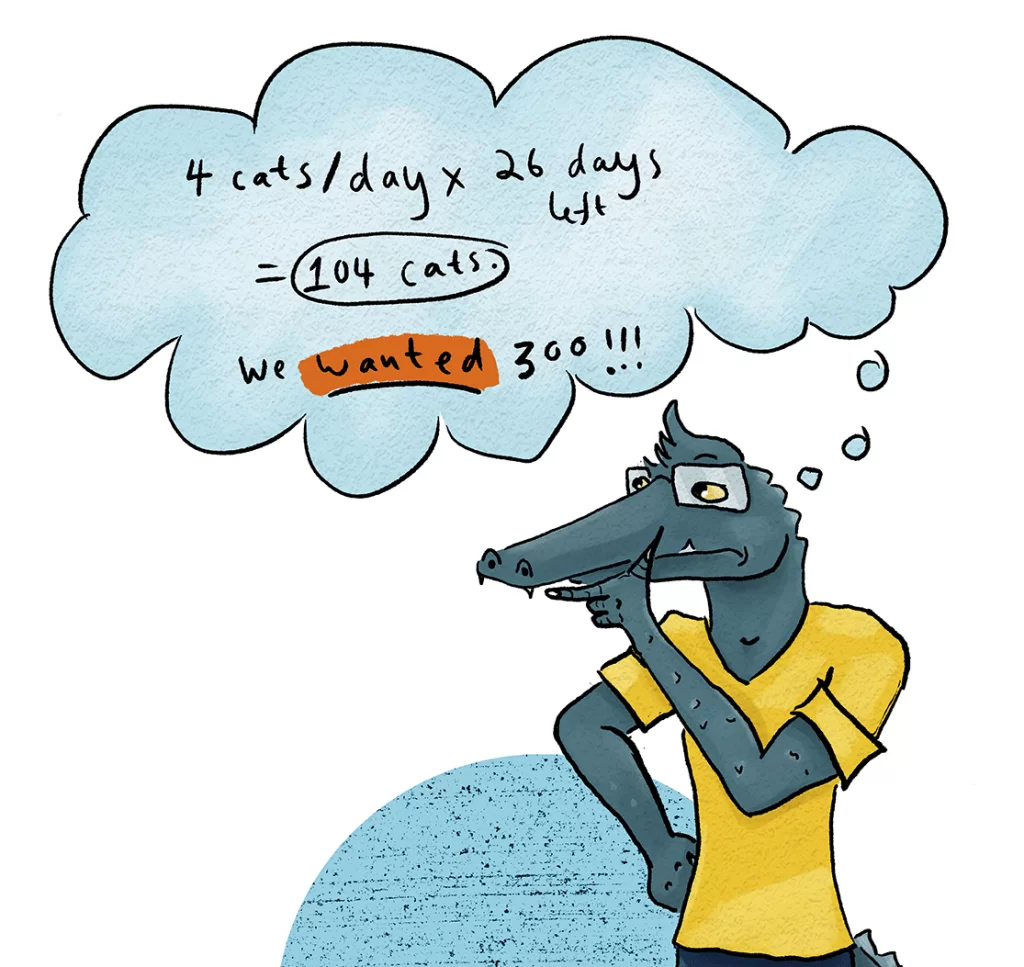

According to Gary’s calculations, it looked like there was no way to make enough figurines without making more molds! And although the material to make more molds wasn’t expensive, it was unfortunately out of stock and on backorder!

It seemed like all hopes of making an army of figurines for Process Cat’s birthday might be lost.

But after combing through a few weeks’ worth of data, Princess Capybara noticed something unusual…

It’s not so much the Mondays as the Sundays…

What?

See, Process Cat’s friends aren’t full-time figurine makers. In fact, each of them has their own business! So they stop by their temporary workshop (they’ve been calling it a Figurine Fab) in the back of Gary’s bakery whenever they can during the week.

Rhonda’s a bit of a night owl, so she normally works in her woodshop in the afternoons into the evenings. So she swings by the Figurine Fab when she’s out for her morning walk, around 11am, to unmold yesterday’s figures and put in the next batch.

Gary, being a baker, works mornings. So at night he’ll unmold Rhonda’s figurines from that morning and put in the next batch before going to bed…

But only when he has the next day off, which is only on Sunday night! See, since Gary has to be up at 3am to start baking, he usually goes to bed too early to unmold the figurines that were put in at 11am.

So what could they do? Rhonda getting up earlier was considered and ruled out as “unrealistic.”

But luckily Rhonda analyzed the data and realized they’d be able to avoid such drastic measures…

See, Princess Capybara is in control of her own schedule, and her workday would allow her to stop by the Fab either in the morning or the evening. She just hadn’t been doing that because her “job” had always been painting.

So in the end, it was pretty simple: Princess Capybara learned how to mold and unmold, and Gary and Rhonda learned how to paint.

All they needed to do was switch to a schedule that allowed them to make 8 parts every day… and adjust the size of their army from 300 down to 208. Still pretty impressive for a prank!

Weekly Challenge:

Perform your own manufacturing capacity analysis! Track how long it really takes you and your team to make parts, and keep a particular eye out for any anomalies! Is there a way you could reallocate your existing resources to increase your capacity?

*Larger-scale manufacturing operations usually factor in machine “uptime,” meaning the average amount of time that the machine isn’t broken or down for scheduled maintenance. As the owner of a smaller-scale business, you’ll probably have a good sense of whether this is important enough in your specific situation to be worth factoring into your calculations.