Industrial Automation

You know that you should consider industrial automation no matter how small your operation is, and you also know that the most important thing to think about when you’re ready to automate is why you want to automate.

(If you don’t? Go back and read the first and second articles in this series first.)

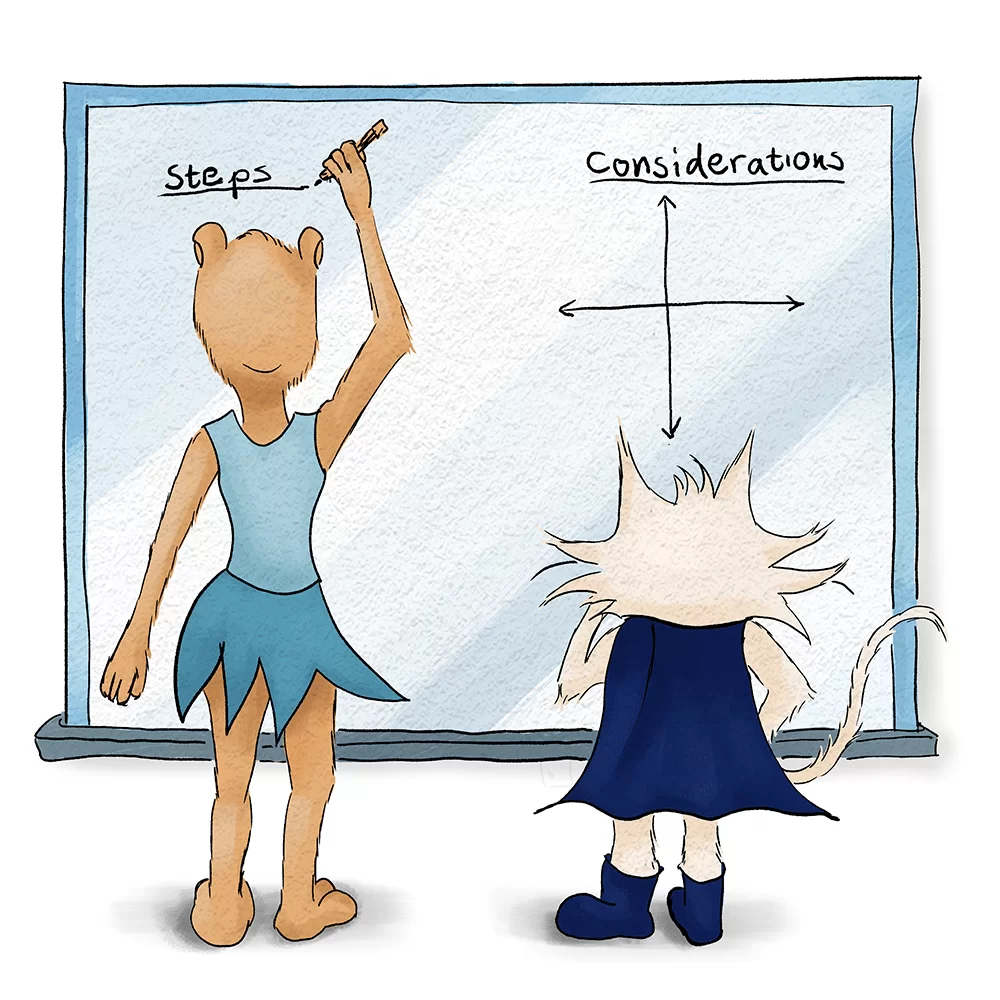

Anyway, the next thing you need to do is go through and list out the steps of your manufacturing process.

Princess Capybara was lucky to have her friend Process Cat to help her figure it out.

If you’re a regular PCat reader, you know that Princess Capybara has a business selling things that she makes out of concrete and that her most recent product is concrete coasters. You also know that she has been overwhelmed with all the work of making so many coasters, so her friend Process Cat is helping her figure out which parts of her process to automate. The first step was to list out all the steps of the process.

Next, you’ll want to revisit…

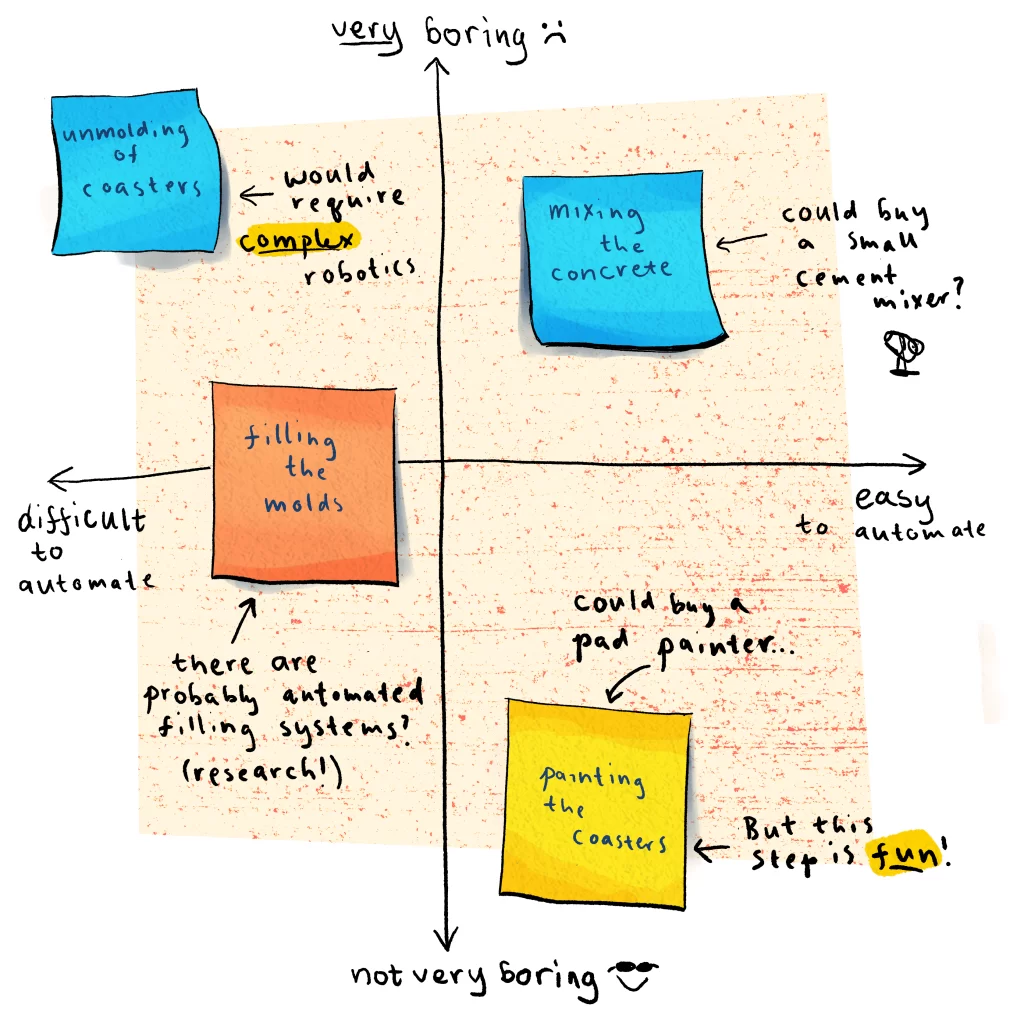

The 2×2 Matrix!

This is a decision-making tool that you may remember from the design thinking series.

You make a plot of two important factors in your decision and then place each item where it fits (qualitatively) on the graph. Here’s Princess Capybara’s:

Note that you might need to do this more than once if more than 2 factors influence your decision. In Princess Capybara’s case, the factors on this graph are ease of automation and boringness of the task. But she also considered the effect on quality of the final product. See, her customers like the handpainted look of her coasters.

Princess Capybara’s reason for automation is to save time on boring tasks so she can have more time for business tasks and creative work. So it wouldn’t make much sense for her to automate the painting of the coasters – that’s the thing that really gives her coasters value, and it’s also the most fun!

But what about mixing the concrete?

Doing that step by hand does NOT add value to the finished coasters (in fact, if anything the coasters might come out better and more consistent if she had a good automated system!)

Same for unmolding the coasters – that part is pretty time-consuming as well, and her customers never say, “Oh wow, look at how well that coaster was unmolded!”

But out of these two options, there is one VERY clear winner as to which should be automated, and that’s the mixing because, as the 2×2 matrix shows, it’ll be much easier to automate!

Why?

Availability of existing technologies!

Meaning, there are already concrete mixers out there in a variety of sizes! The technology is very established and she can likely buy a used one at a reasonable price. Whereas designing a coaster-unmolding robot would literally involve designing a new robot or hiring a design firm to do it.

So Princess Capybara starts shopping for a small concrete mixer, and soon that part of her process is

Weekly Challenge:

Look through your own processes and use the 2×2 matrix tool to help you decide which steps (if any) you want to automate! Then, read your easy introduction to robotics!