You’re committed to improving your manufacturing process. Because you take pride in your business and you want to deliver a high-quality product while making solid profits. And if you’re a regular PCat reader, you know that the best way to do that involves root-cause analysis for any manufacturing defects that crop up! But did you know that there are several different approaches to root cause analysis?

Gary didn’t…

If you don’t know him yet, Gary was an accountant in his 40s who recently took his side business (baking cookies!) full-time.

But, recently he’s been having problems with cookies tasting like baking soda! And no one wants that. So he asked Process Cat and his other friends for some help finding the cause. (Link: last time) he tried Ishikawa’s Fishbone Diagram, which can be an excellent tool for identifying the cause of a manufacturing problem. But it’s far from the only tool out there. So this week he decided to try…

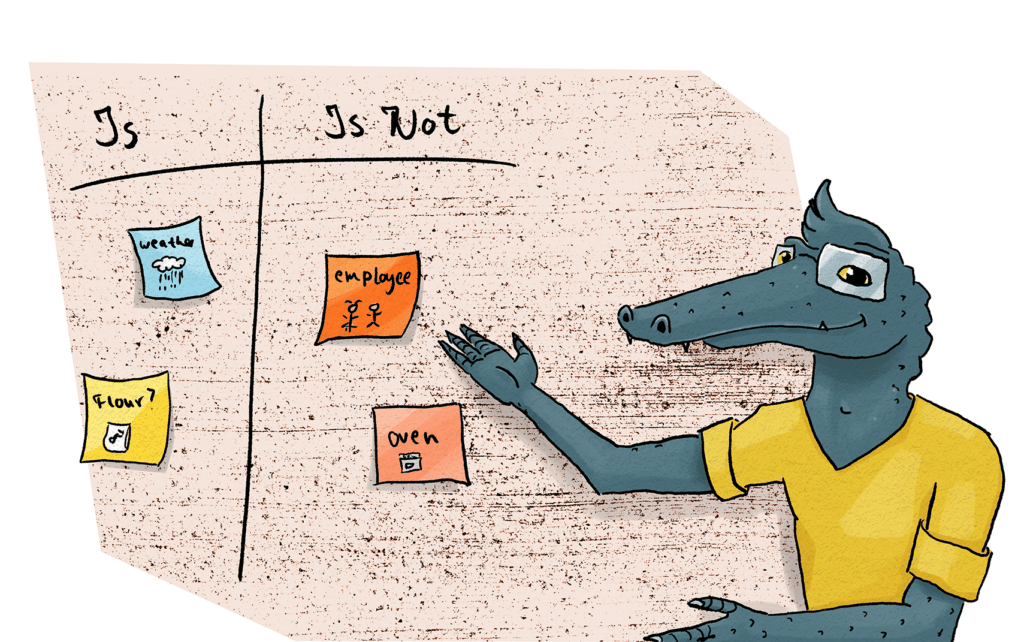

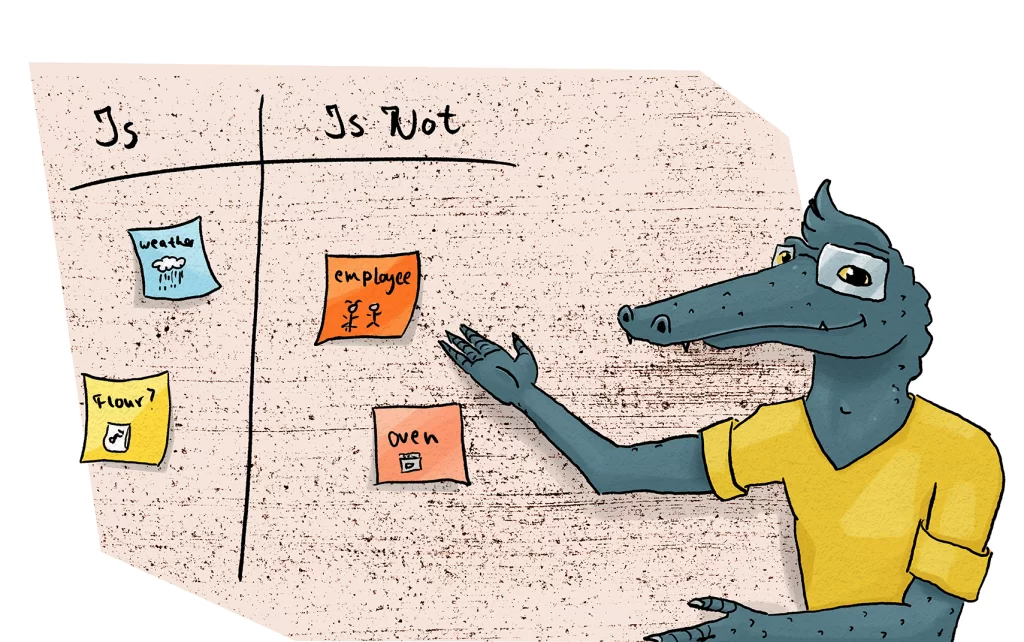

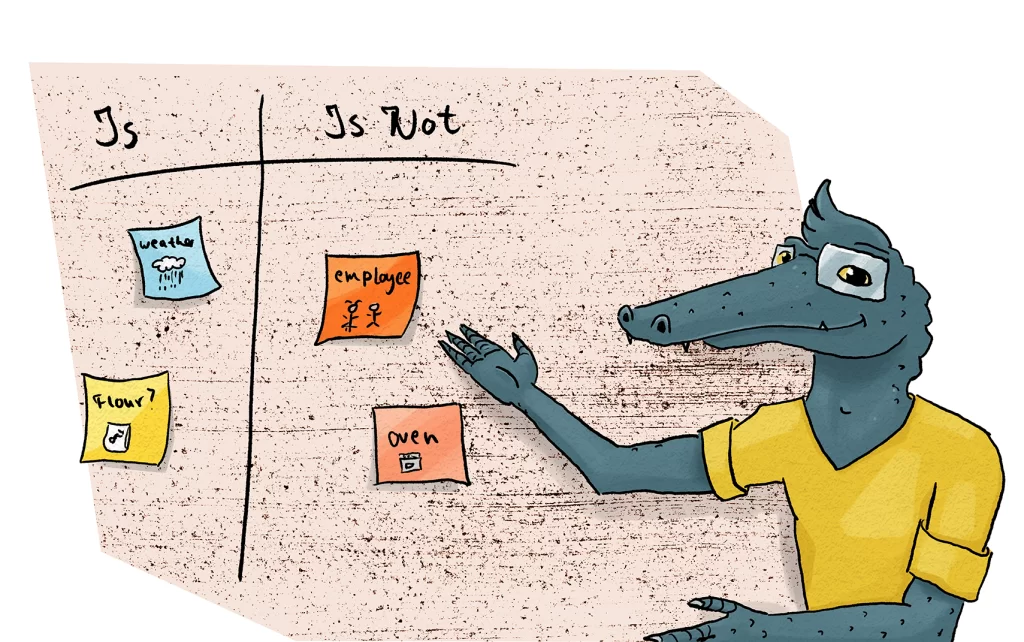

Is-Is Not

Is-Is Not is another tool for identifying the root cause, and it’s a bit less formal than the Fishbone Diagram. With Is-Is Not, you just look at what situations the problem is and is not observed in, which in turn gives you clues about what the problem is and is not!

Now that’s admittedly a little vague! But it makes sense in practice.

For Example:

Gary has two different ovens.

Looking back over his records, Gary finds that the problem of baking soda-tasting cookies IS present sometimes with the new oven, and it also IS present sometimes with the old oven.

This means that the problem most likely IS NOT the oven.

(You see why, right? If the problem was caused by a problem with one of the ovens, we’d expect to only see it with that oven. But since the problem occurs sometimes with one oven and sometimes with the other, it’s more likely* caused by something else.)

So Gary is able to eliminate some potential causes simply on the basis of Is-Is Not.

But what about the IS part of Is-Is Not???

Glad you asked 😉

When Gary looks back through his records, he notices that the problem IS NOT ever occurring with the flour from the old shipment…. but it IS sometimes occurring with the new lot numbers of flour. That means that maybe the problem IS the flour!

And that’s a very important point: don’t jump to conclusions with Is-Is Not. Gary still needs to do some experiments to determine whether or not the flour is really the cause of his nasty-tasting cookies. But for now, he puts flour on the potential “is” list.

And he goes through the rest of the elements of his process and makes similar determinations.

Weekly Challenge:

Are you troubleshooting a tricky manufacturing problem? Use Is-Is Not to help structure your thinking! And come back next time for another tool, the Pareto Distribution.

*Note that it’s still not technically impossible that the problem is caused by the ovens! It absolutely could be that both of the ovens are malfunctioning in the same way at the same time. But since the ovens are vastly different and the problem is occurring with both of them, it’s more likely that something else is the cause. Once again, it’s important to remember that Is-Is Not is a tool to help guide your investigation – it’s not infallible proof!