You know that automation is important to understand as you start to scale your Maker business. Now, let’s do an easy crash course in robotics. You may or may not end up using robotics in your manufacturing business (your business, your decision!), but you can’t make an informed decision until you at least understand the basics, right?

Gary was suddenly ready to jump into using robotics….

If you’re a regular PCat reader, you know that Gary is an accountant in his 40s who has a side business baking cookies.

But what you may not know is that Gary had a very wealthy, childless uncle. Unfortunately, that uncle recently died, but he had a very good life and a peaceful end.

And, importantly to our story, Gary found out a short while later that the uncle had left Gary a LARGE sum of money. Gary decided to invest most of it into scaling his business in a big way! He jumped on the subway over to Process Cat’s apartment, and texted him from the sidewalk:

Well, that was an odd text to get at 3pm on a random Sunday, but Process Cat was happy to oblige once he realized Gary wasn’t joking. Process Cat invited Gary in and told him about

The characteristics of robots

Yes, we should back up, shouldn’t we? What exactly is a robot as opposed to another type of machine?

The official definition is that an industrial robot is

An automatically-controlled, re-programmable, multipurpose manipulator that is programmable in 3 or more axes…for use in the automation of industrial tasks.

International Federation of Robotics

Talking about this from a Maker business perspective, though, you might find it easier to think in terms of the attributes of a robot. Basically, an industrial robot usually has most* of the following:

- Some way to be programmed (yes, ok, technically it should be able to be re-programmed, meaning it’s not just programmed once at the factory that made it but can be given new instructions by the owner of the robot.)

- Some way of affecting the physical world. (Note that there are robots that don’t do this! Automated customer service chat-bots are a type of non-physical robot. But, for industrial robots, causing some sort of physical effect – like moving a part – is required.)

- Sensors for receiving information from the outside world (cameras, for example.)

Ok, so that’s what a robot is. Now let’s talk about…

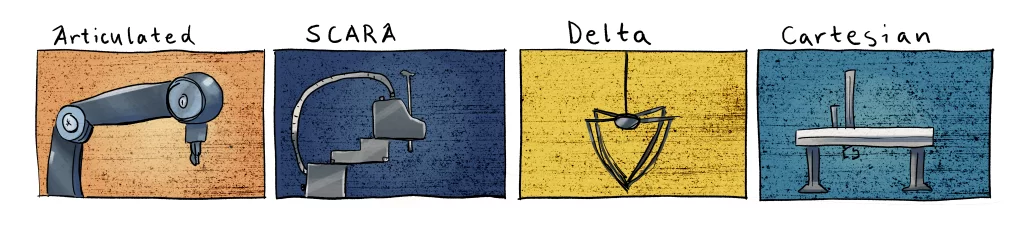

The 4 Main Types of Robotics

Yes that’s right, there are only 4 main types of robot assemblies that you need to understand! That’s easier than you thought, isn’t it? Anyway, here they are:

- Articulated robotics assemblies are a good place to start because they’re the ones that most people think of. Articulated robots work somewhat like a human arm or leg: they have several joints, each of which can rotate and bend.

- SCARA robots (stands for Selective Compliance Articulated Robotic Arms) move only in two planes, so they are less flexible than Articulated robots. But, they do have a high level of accuracy so they’re good for things like precision insertion tasks.

- Cartesian robots move only in one plane. A popular example of a cartesian robot is an FDM 3D printer: the printer head moves only in an x,y plane, depositing material.

- Delta robots (so-called because they often have a triangular shape, especially if they have 3 arms) can be thought of as little hands – they are not particularly accurate, but they are very fast…

And for that reason, Delta robots are very popular in the food industry! It’s important that the cookies be picked fast from the conveyor belt, but it’s not that important exactly which cookie the robot picks first. So Gary buys some Delta robots….

Weekly Challenge:

Understand these types of industrial robots and think about whether any might be useful in your business – but don’t forget to factor in what to automate in the first place when making your decisions!

*Sorry to be so wishy-washy! But the term “robot” really doesn’t have one universal definition that everyone agrees on, especially not one in plain English. This is about the best I could do :p

Ps. If you want to read more about robotics, check out the International Federation of Robotics