Everyone has been talking about supply chains recently – with good reason! Supply chain management is an important topic for making and manufacturing businesses of all sizes.

Rhonda started reading about supply chains.

If you’re a regular Process Cat reader, you know that Rhonda is a retired nurse who now runs a business making wooden items in her garage workshop and selling them at craft fairs.

Unfortunately, Rhonda’s first reaction to the supply chain news was to panic and buy way too much wood.

Luckily, Rhonda’s friend Process Cat was able to calm her down and convince her not to panic. But he was glad for her new interest in supply chains because it’s an important topic! Basically, a supply chain is the series of businesses between a raw material – wood, in Rhonda’s case, and the final customer – Rhonda’s customers. (You can read more about that in the last article.)

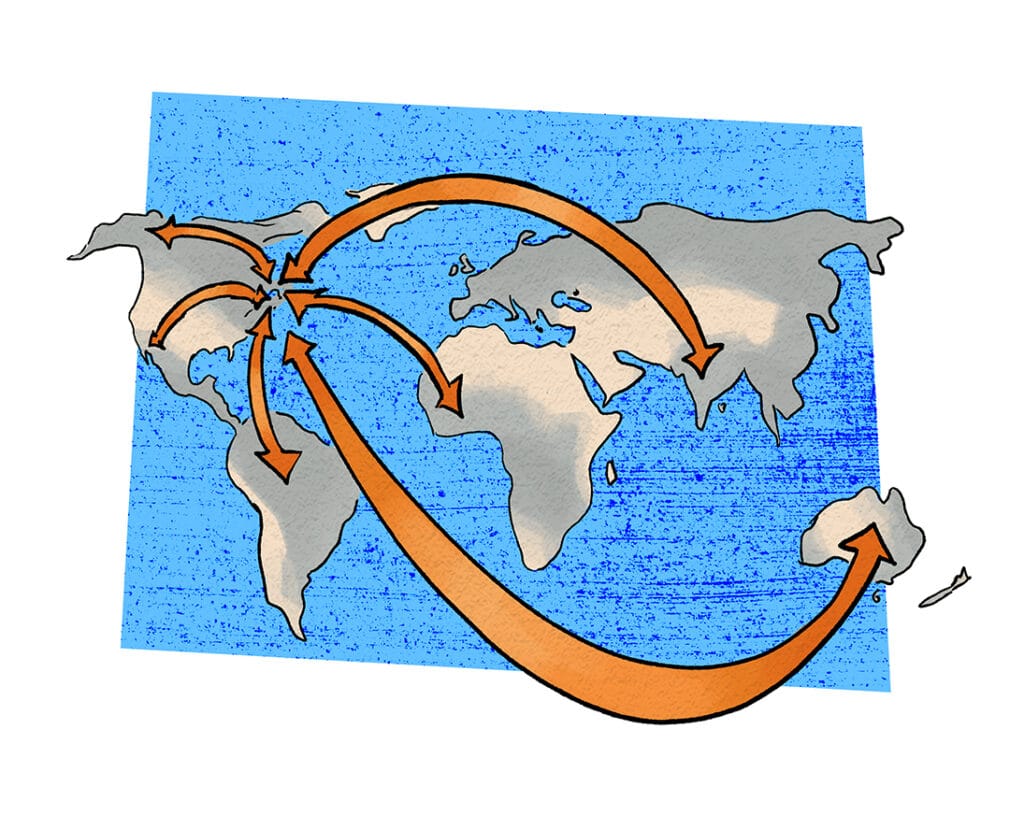

So why have supply chains been so big in the news recently? Well, over the last 50-75 years, some important things have happened in supply chains: they’ve gotten more complex and more global, and they’ve also become a lot more efficient! Much of that increased efficiency is due to 2 interrelated concepts:

- The Toyota Way

- Lean Manufacturing

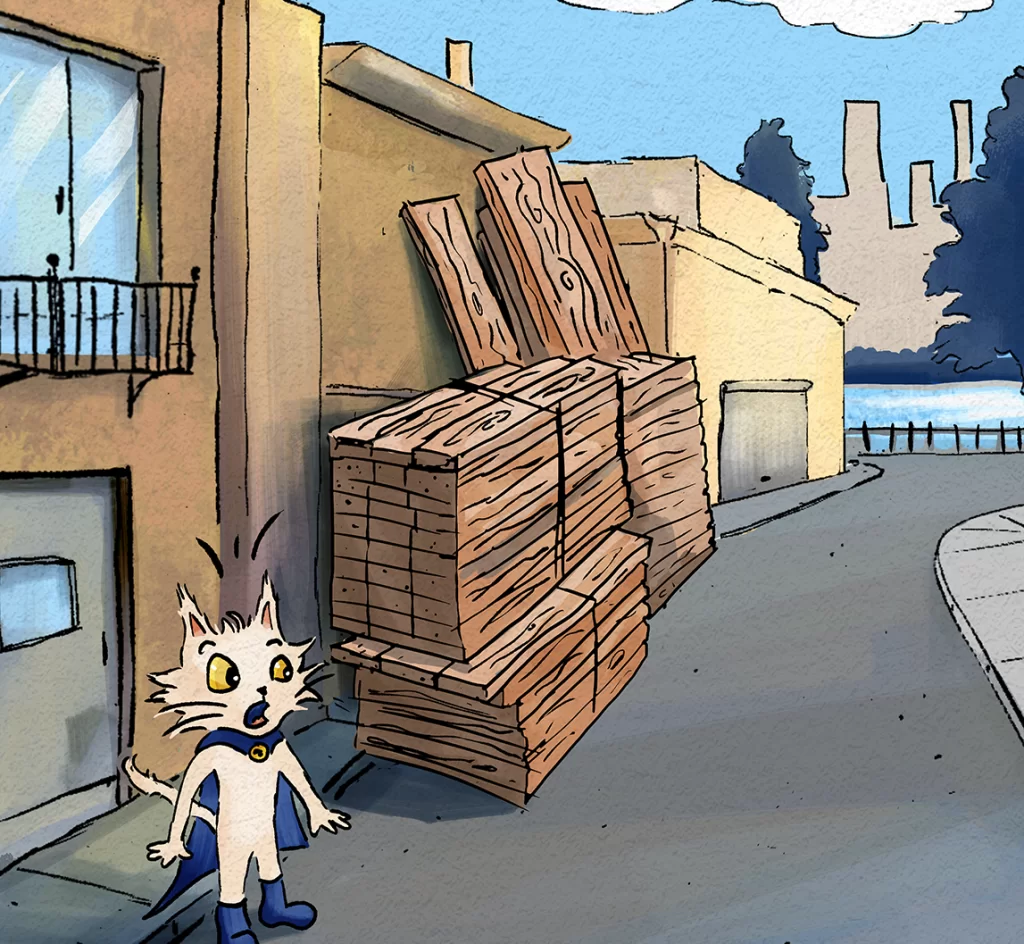

Lean Manufacturing is mostly about eliminating “waste.”

Yes, it’s true! Avoiding unused machine capacity, unnecessary staff, and excess inventory is a great way to reduce costs and therefore increase profits without raising prices for customers. And in general, it’s also better for the environment to avoid waste too.

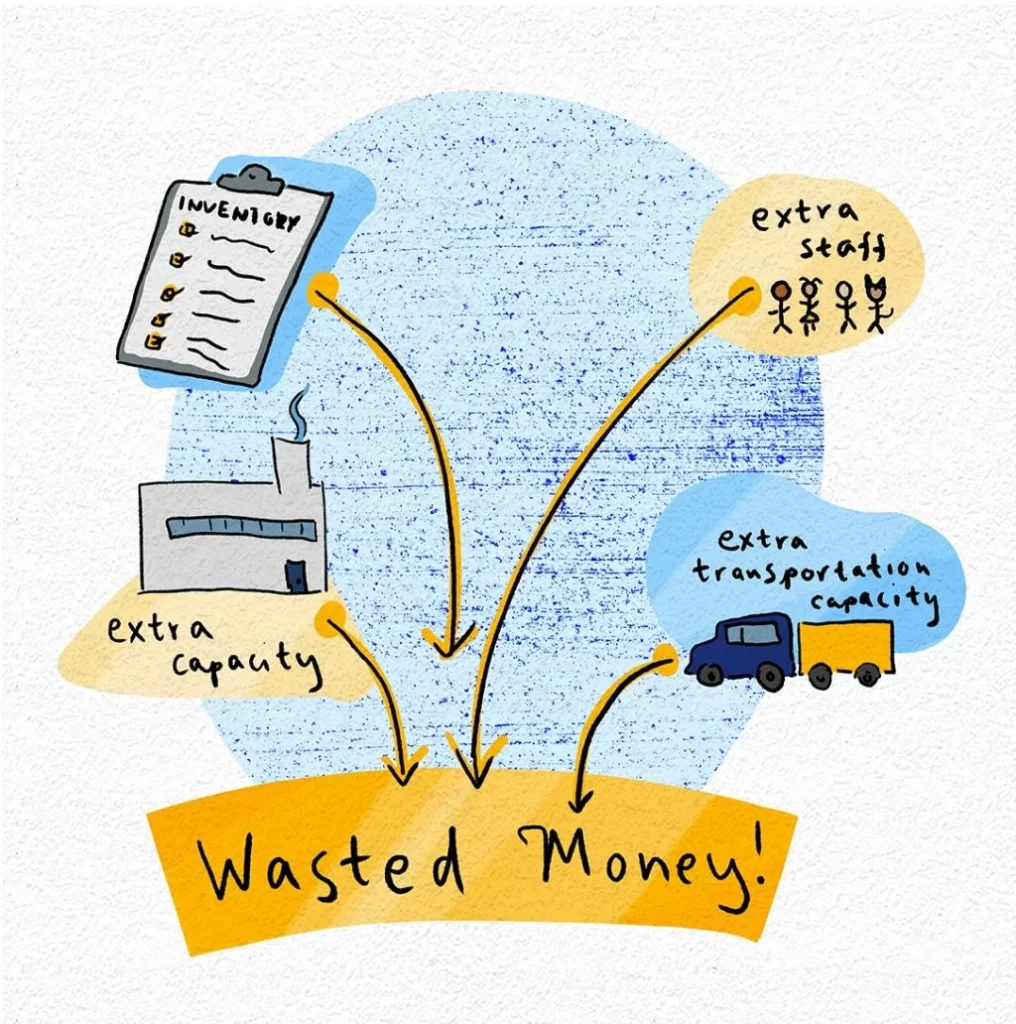

BUT, eliminating everything extra does come with a “cost” of another type:

Yup, that’s one downside to eliminating everything that looks like “waste” – it does mean each link in the supply chain has less resilience. So when demand from its customer (which might be another business also following lean manufacturing principles) increases, it doesn’t have extra inventory on-hand or extra equipment capacity and extra workers to quickly make it! It also doesn’t have extra supplies stored in case its supplier (who is also another business doing the exact same thing!) has a shortage.

So, well, “shocks” of various types get propagated through the chain.

Look, no one’s saying completely get rid of Lean Manufacturing!

It’s been a very useful strategy that’s done plenty of good for our global economy and our standards of living. But Supply Chain professionals and industry groups are starting to rethink the standard strategy of waste elimination at all costs.

Weekly Challenge

Look through your own business and think about whether investing in a little extra inventory, supply stock, and/or capacity might actually be useful!

Ps. Hungry for more on this topic? Check out this year’s report from ASCM, the Association for Supply Chain Management. They go a lot more in-depth with other things you can do besides what we’ve mentioned here 🙂