Everyone knows that if you’re shipping your products through the postal service or through a service like UPS or FedEx, they’ll need some packaging for protection. Even in your home life, if you’ve ever mailed something fragile you know that an important consideration is how to prevent it from getting damaged during shipment. But you may not have heard of pre-shipment testing.

Once you started shipping your manufactured items for your business, you probably realized that you would need to consider packaging. You may have even had the idea to do some little tests of your packaging, like throwing the box around a little or shaking it, then taking your product out to see how it held up. Or maybe you just tried sending some samples of your product (packaged in different ways) to a friend to see which ones held up the best. These are great starting points!

But did you know that there is an organized and systematic way for doing pre-shipment tests? Specific tests that have been developed to predict how well-protected your product is for the specific conditions it will encounter during shipping?

Gary didn’t.

If you’re a regular PCat reader, you know that Gary makes cookies. He sells the cookies online and ships them to his customers.

Gary knew that customers wouldn’t want broken cookies, so at first he wrapped them extra-securely in layers of bubble wrap and then placed that in a cardboard box.

The cookies arrived securely but there were two problems with this approach: 1) It got expensive! 2) Customers started complaining that his packaging was wasteful and bad for the environment (and Gary knew they were right!)

So Gary decided to switch to packaging the cookies in just a padded envelope. But this approach had a disadvantage as well.

Clearly, that was going too far. So Gary asked his friend Process Cat what he should do. Process Cat recommended Pre-Shipment Testing!

What’s that? Glad you asked 😉

Pre-Shipment Testing

The International Safe Transit Association (ISTA for short) publishes testing procedures that replicate the forces and impacts a package is likely to experience during shipping.

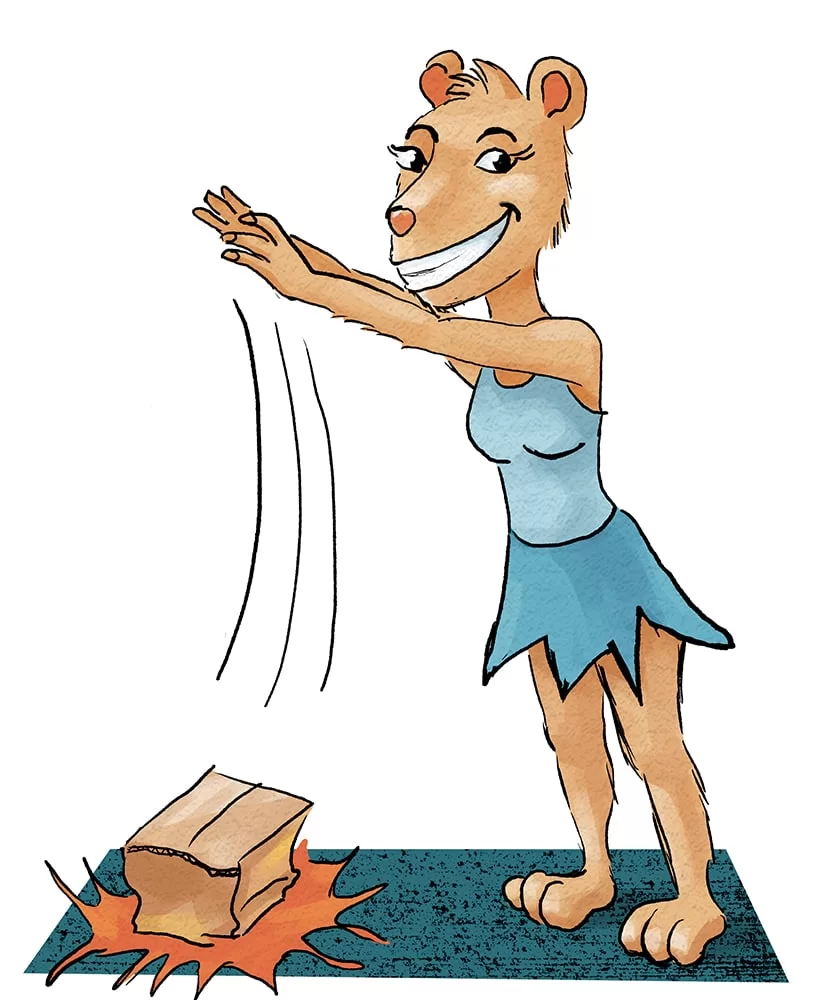

In Gary’s case, Process Cat recommended the widely-used Drop Test. You can read about the specifics of the standardized Drop Test at ISTA’s website, but basically, by dropping your packaged item from standard heights in various orientations, you can simulate what your package will experience during rail, truck, or air travel and in-person handling.

So Gary made a whole batch of cookies and packaged them in a bunch of different ways. Then he invited his friend Princess Capybara over to help with the testing.

After doing the drop-tests (several times, to get good data!) Gary and the Princess figured out which packaging system provided enough protection that the cookies would arrive unbroken while minimizing the number of wasted packing materials.

Weekly Challenge:

Look at the packaging system you use when you ship out products. Do customers consistently receive their products undamaged, without you spending too much money or producing a lot of waste with the packaging? If so, you might not need to worry about this.

And if your pre-shipment testing reveals some problems? Read the next article in this series to learn how to prevent those packaging failures!