Everybody knows that automation can be a useful strategy in scaling up a manufacturing operation. But did you know that there’s one easy-to-make mistake that can cause you to waste time and money when you’re doing that automation?

Princess Capybara didn’t know at first…

If you’re a regular Zattatat reader, you know that Princess Capybara ditched her first career as a biotech executive.

For her second act, she started making molded products out of concrete. Her best seller is the Secret Wine Glass.

Anyway, just because she decided to do something more fun for her second business didn’t mean that Princess had lost any of the drive and ambition that made her successful in her first career. So before too long, she’d built up her business from a garage workshop to a manufacturing operation with employees. And demand for the Secret Wine Glass was high enough that she was now ready to start…

Automation!

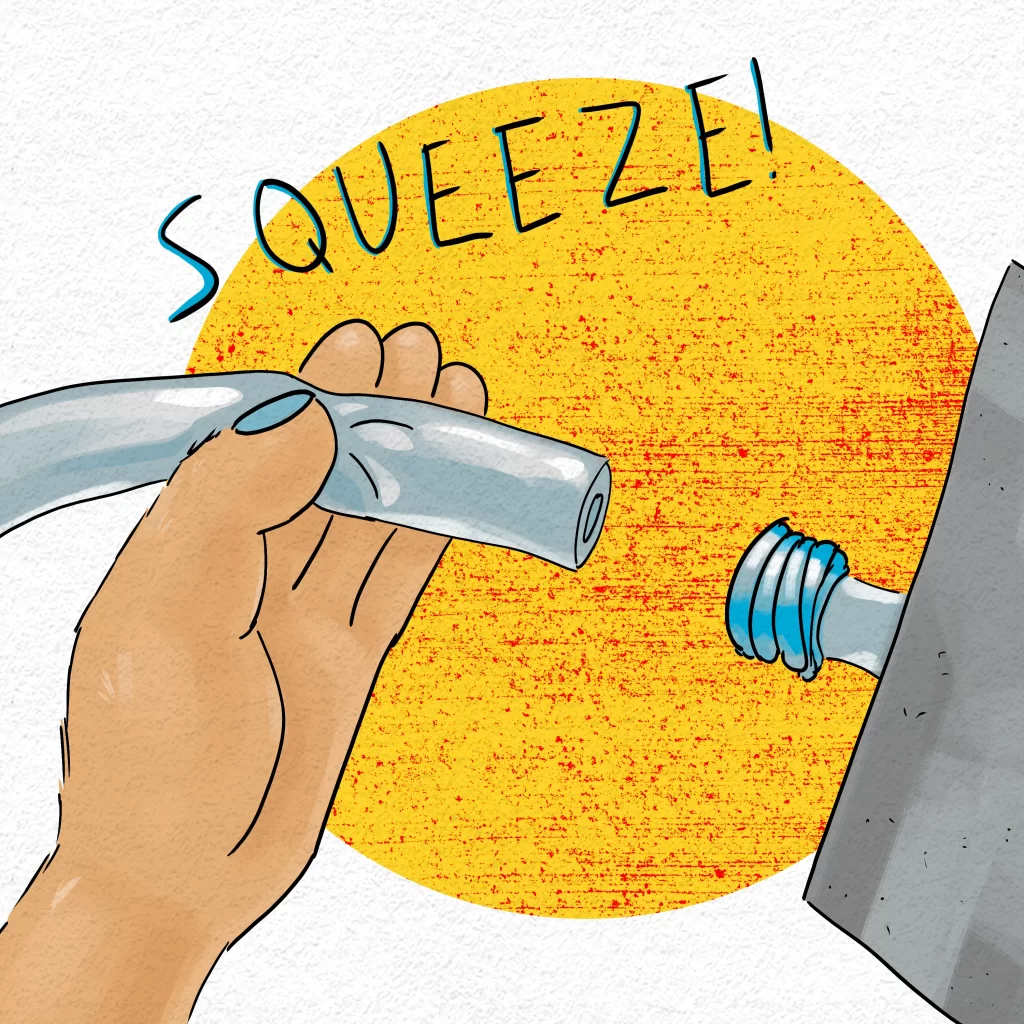

Yes, as you remember, there are many reasons to start automating parts of your manufacturing process as you scale up. (If you don’t? Check out this article to jog your memory!) Anyway, being a competent and compassionate leader, Princess Capybara decided to automate the step in Secret Wine Glass production that was starting to give people hand injuries now that they were making hundreds of Secret Wine Glasses per day! Namely, attaching the rubber tubing to the nozzle.

So, the Princess asked around and found a company that could help her design an automated device to attach the rubber tubing (which would still be cut manually) to the nozzle of the Secret Wine Glass (which would also still be assembled manually.)

But when she brought a few of her best operators with her to look at the prototype for the newly designed apparatus (which you should always do for the best chance of a smooth rollout!), Princess Capybara was made aware of a fairly major oversight. Namely?

Or to generalize a bit?

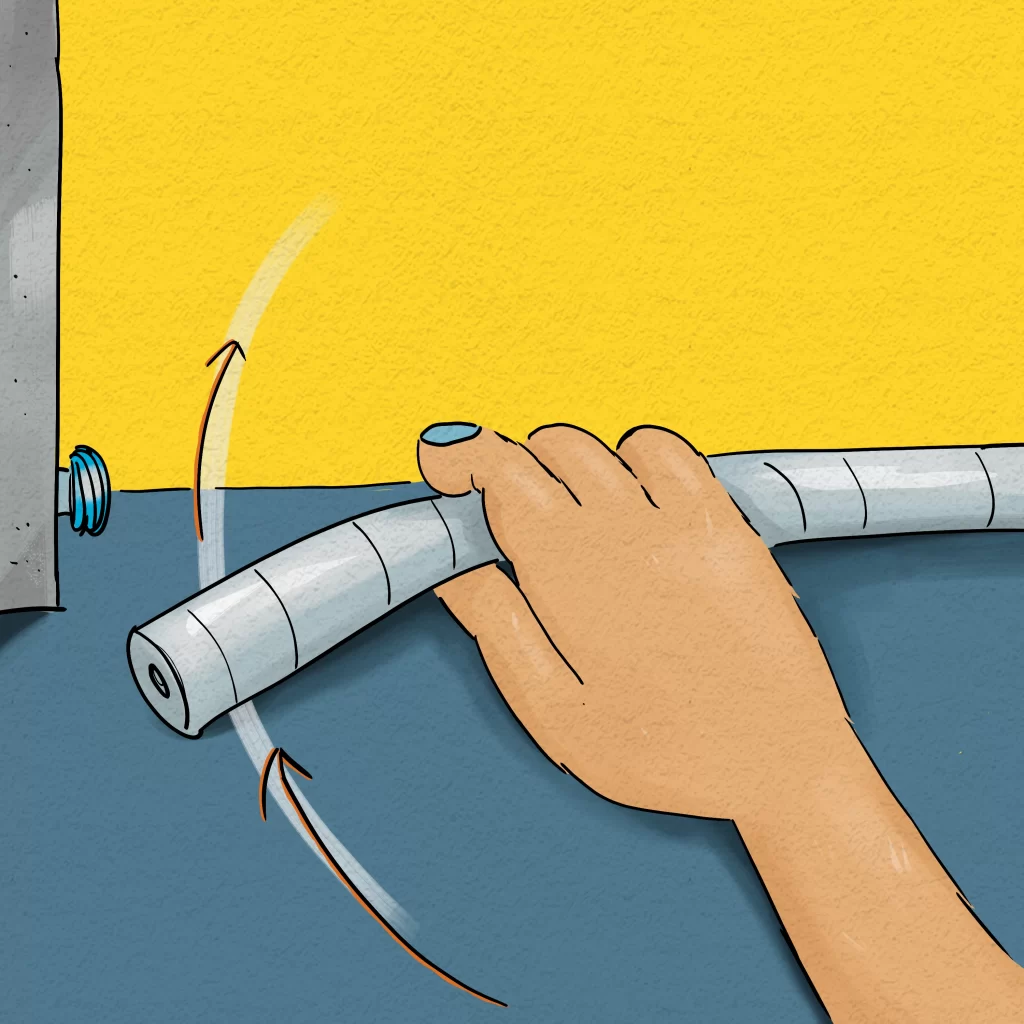

When automating a manual process, pay attention to ALL of the things the person is doing!

See, human hands (and wrists and arms) are capable of a very high number of different movements. Human brains are sophisticated, so they can quickly and often unconsciously notice how a piece of material needs to be manipulated and perform the manipulation (as in the above example of moving a piece of tubing into position.)

But robotic systems are… for lack of a better word, clunkier. For details on that, check out this article where we talk about the specific types of motion that robotic systems can perform. But the basic point is, that an automated system will only do exactly what it’s designed to do. So you’d better make sure that you’re aware of all of the things it needs to do.

With gratitude to her operators for pointing out the problem, Princess Capybara was ultimately able to work with her contractor to modify the design and get a system that would work.

Weekly Challenge:

Are you getting ready to automate a step of your production system? If so, learn from Princess Capybara’s mistake and pay VERY close attention to exactly what the human operator is doing!