You want manufacturing advice. (If you don’t? You’re reading the wrong website, my friend!)

Yes, at Process Cat we talk about manufacturing – how to make improvements in your own processes or advice on working with a contract manufacturer, for example.

Today we’re going to back up and answer a more basic question, “What exactly IS manufacturing?”

Everybody has a basic understanding that “manufacturing” is basically “making things,” just at a larger scale, and that’s generally correct. The main* differences between making a few of something and doing it at scale are process optimization, and different technologies at different scales.

IMPORTANT: There are also safety and legal requirements that come into play when working at scale! And we do talk about those in other articles. But for today we’re talking about the technical side of manufacturing.

Princess Capybara didn’t always understand what manufacturing was.

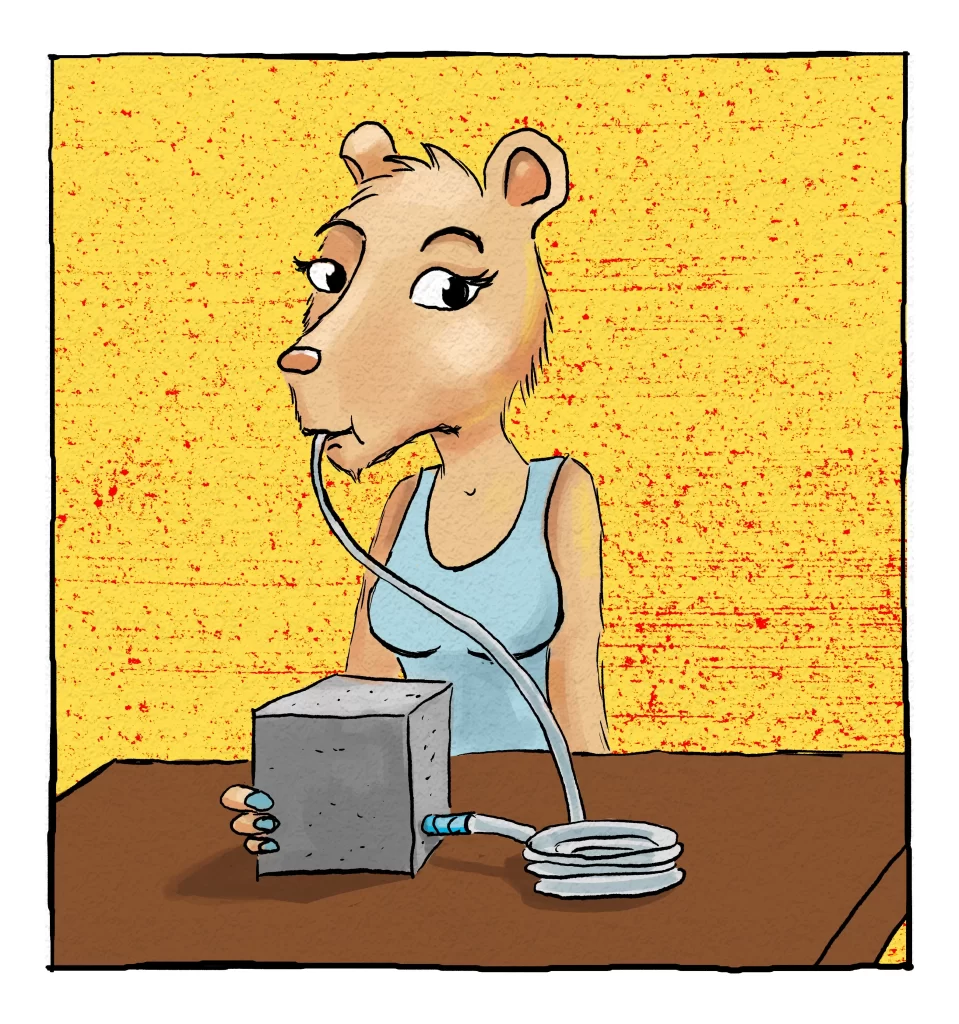

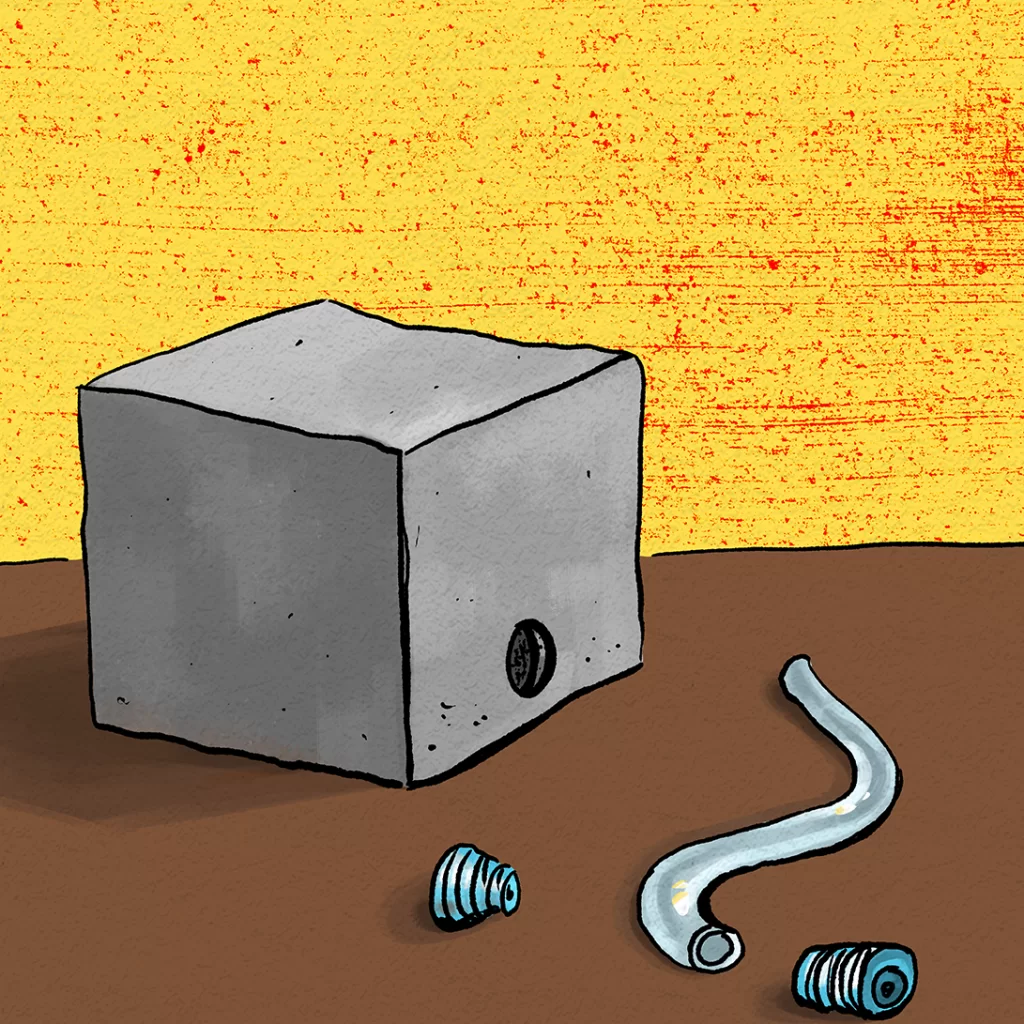

If you’re a regular PCat reader, you know that Princess Capybara molds concrete items in her workshop. Her favorite is the Secret Wine Glass, a concrete and block-shaped wine vessel with a tube for a straw so that people can SECRETLY drink wine.

But Princess Capybara’s first business was a more “traditional” start-up that she founded with some of her classmates from business school. After a few years she had what you’d call a “corporate” job as the head of marketing.

Back then, the Princess assumed she’d be outsourcing her manufacturing. As she got closer to launching her business, though, she asked her friend Processs Cat for his advice.

Process Cat didn’t try to dissuade Princess Capybara from hiring a contract manufacturer. It can absolutely be the right choice for some entrepreneurs, and for some situations! But he did help clear up some of her misconceptions about what “manufacturing” the Secret Wine Glass would and wouldn’t be.

See, Princess Capybara had assembled her prototype by molding the body of the “wine glass,” then adding some food-safe plastic tubing and some fittings from her local hardware store.

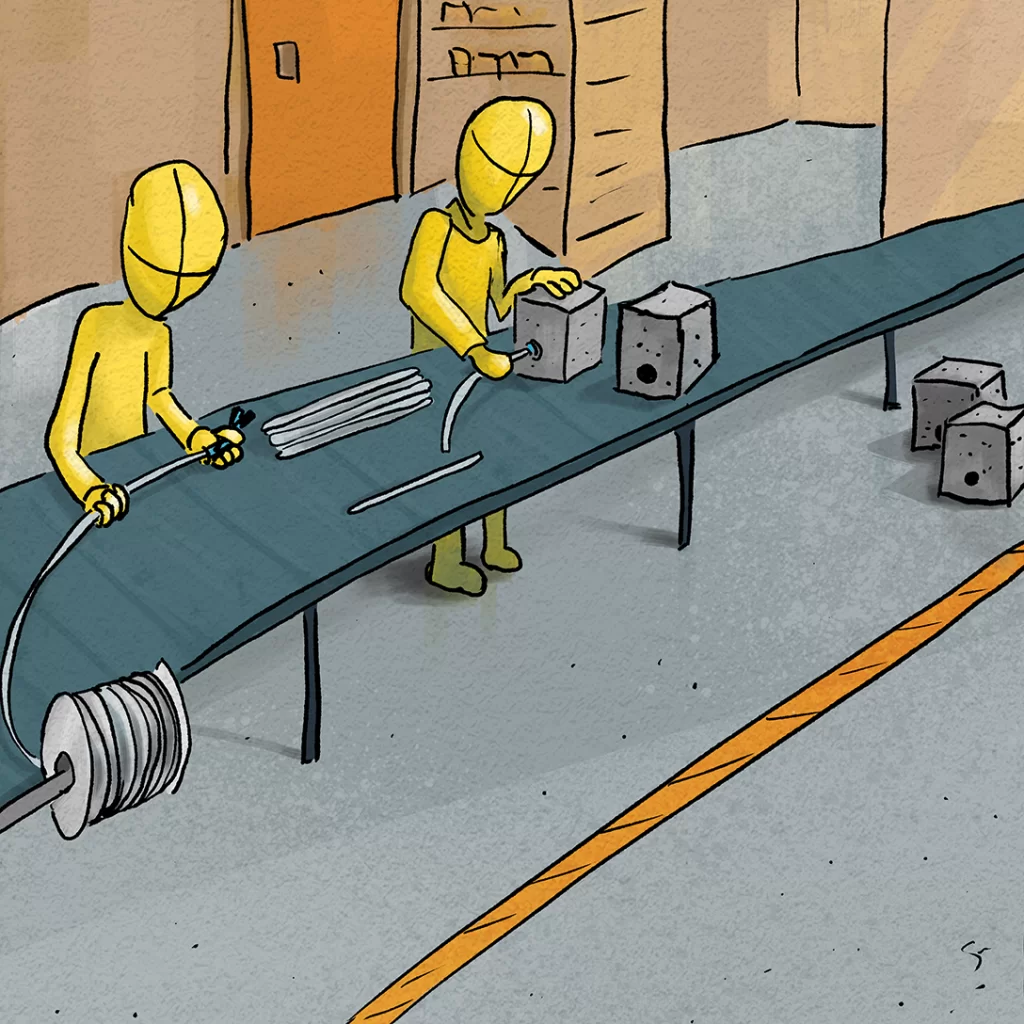

Actually yes, I do have and idea how they’ll “manufacture” this product

- There will be more workers, in a larger facility.

- They’ll have sourced the materials from a larger supplier so they can have better selection and better prices.

- They’ll have optimized the molding process and implemented monitors and controls. (For example, they might use a thermometer to make sure the water in the concrete mixture is at a certain temperature when it goes in.)

- They might automate some steps of the process, like the mixing of the concrete.

- They’ll be following more rules about safety, waste disposal, and other things.

- But at the end of the day…

Yes, it’s true: “manufacturing” something is not always categorically different from “making” something.

Wait a minute. Not Always? Are you saying it is sometimes???

Well…yes. And that’s because SOMETIMES when you cross a certain volume threshold, it makes sense to change to an entirely different manufacturing technology! If you want to read about that, come back for our next article. Until then… happy making!