You have an outstanding product and people are buying it! Now it’s time to package it for shipping. But how do you prevent packaging failures? If you’re just starting out on this topic, you might want to read the first and second articles in this packaging series before this one. If you’ve already read those, you know how to identify your product’s relevant conditions and how to conduct pre-shipment testing.

So what do you do next, after your pre-shipment testing? Well, if your product “passes” the pre-shipment testing packaged the first way you tried, you could decide that you’re done. You’re a busy business owner and you might not care about optimizing as long as your packaging works. But what if your pre-shipment testing reveals some problems?

Remedies for Packaging Failures

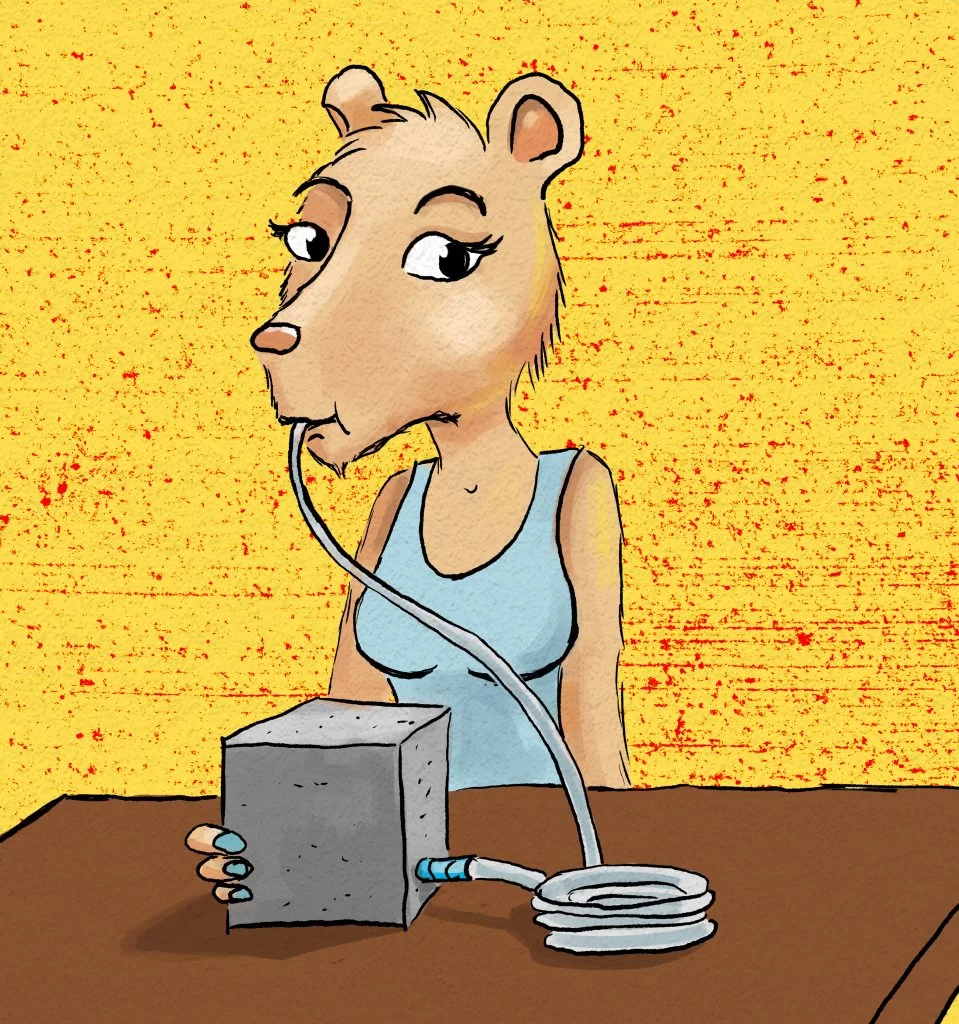

That was the case for Princess Capybara….

Yes, you regular PCat readers remember that the Princess makes molded concrete items in her workshop, and her most recent product is the Secret Wine GlassTM.

She sells the glasses online using a fulfillment service (something like Fulfillment by Amazon or FedEx Fulfillment.)

What does this mean?

This means the Secret Wine GlassesTM needs to withstand special stressors in the warehouse environment AND the usual ones from truck or train shipping.

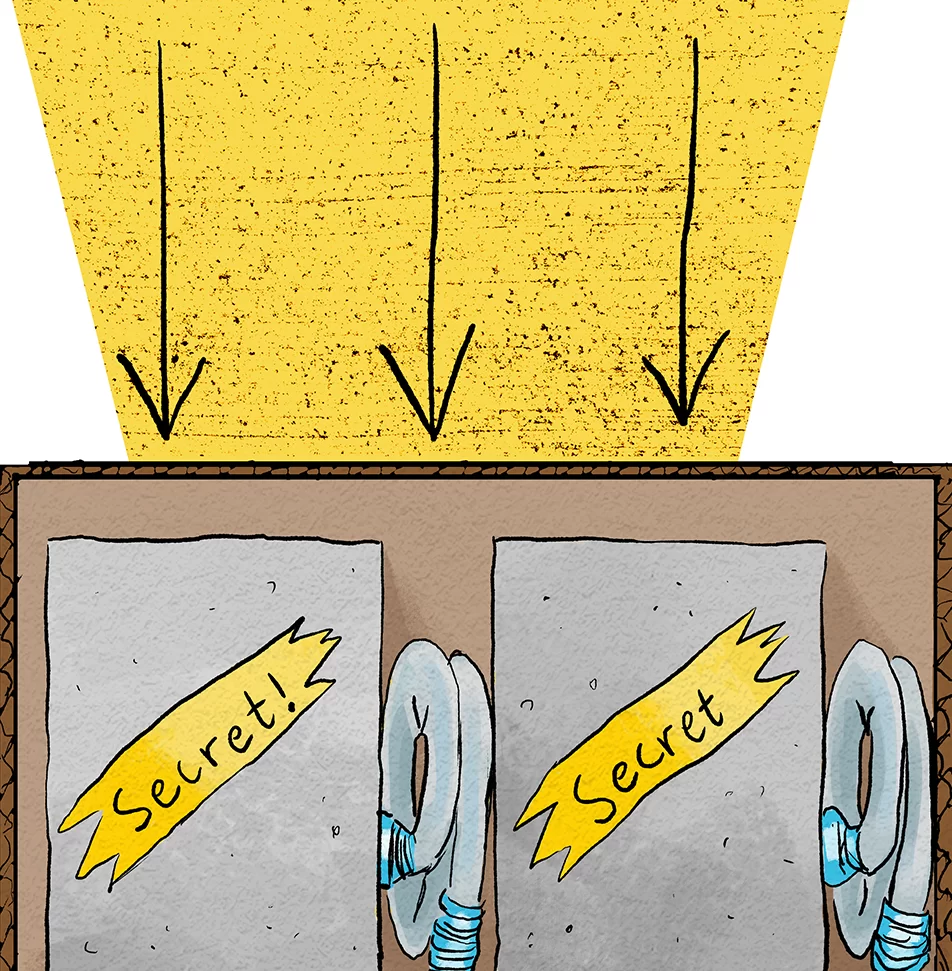

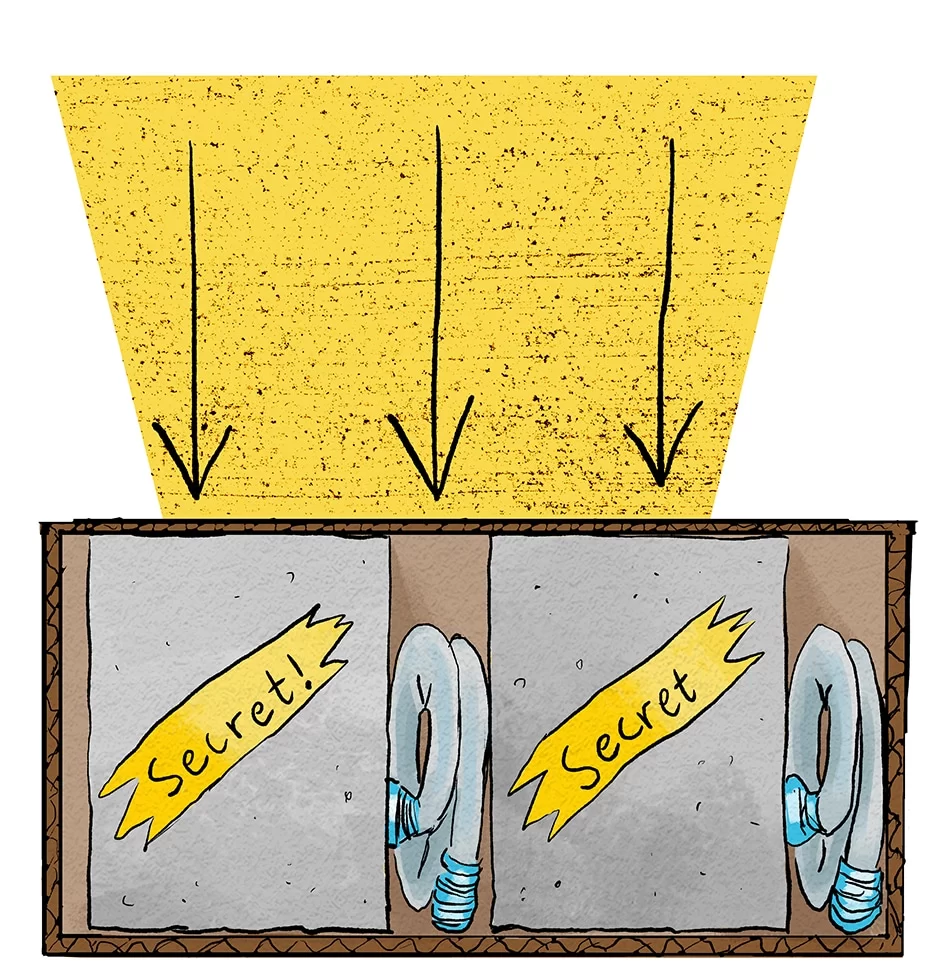

For example, all the stacking that happens in a warehouse means that the package assembly needs to be high in compressive strength. Compressive strength means something can withstand force pushing on it. In this case, the box at the bottom of the stack will have the weight of all the boxes above pushing on it because of gravity.

If you’ve read the article on materials properties, you know that concrete is high in compressive strength. (Which is why it’s often used for things that need to withstand a lot of compressive forces, like bridges and sidewalks.) But Princess can’t just ship the Secret Wine GlassTM by itself for several reasons:

- Scuffing

- The spout might break off

- Requirements of the fulfillment partner.

So Princess Capybara packages the Secret Wine GlassesTM in a cardboard box.

Unfortunately, this leads to an unforeseen problem: the walls of the cardboard box are not nearly as strong in compression as the concrete!

When she stacks the boxes of Wine Glasses, the package fails before the product. Which is a fancy way of saying…

Luckily, Process Cat has some advice.

So Princess orders some smaller boxes and is pleasantly surprised:

Wait, that’s it?!

It’s really that simple! And in fact, you’ll probably notice products that are packaged this way if you shop in bulk stores – bottles of shampoo or laundry detergent, for example, are typically packaged so as to take advantage of the compressive strength of the bottles. Big companies are decreasing their packaging failures potential the same way you can!

Now, depending on your specific product you may find different things when you do your pre-shipment testing. The point is just to be aware that small changes to your packaging system can have a big effect on how well your product stands up to shipping and warehousing.

Weekly Challenge:

Do some pre-shipment tests for packaging failures and see how your product and package hold up. See if you can think of any simple modifications to improve your system!

Ps. Need more information? Check out ISTA or the Institute of Packaging Professionals’ book on the subject.