Intro to manufacturing technologies

You’re already confident making things and selling them. Because you’re a maker, manufacturer, entrepreneur, creator, or whatever you choose to call yourself. But have you ever hesitated when you had an idea for a new product, because you realized you weren’t 100% sure about the best technology to make things outside your immediate wheelhouse?

The Zattatat gang realized that they all had…

If you’re a regular here, you know that the Zattatat gang consists of several small manufacturers: Rhonda, a retired nurse who now makes and sells wooden coasters and beer mugs; Gary, an accountant who has a side business as a baker; Princess Capybara, a young serial entrepreneur whose recent endeavors have included biotech, concrete molding, and skin serums; and Process Cat, a manufacturing engineer who left his corporate gig to become a manufacturing superhero who helps small business owners solve their manufacturing problems.

Anyway, recently they were all hanging out and realized that they had all had the same problem recently: not being totally confident of the best way to make a new product.

Since the gang had recently convinced Process Cat to give a master class in process controls and found it valuable, Princess Capybara suggested they ask him to do another one, this time on the topic of manufacturing technologies.

Process Cat was all to happy to oblige, and suggested that they start with…

Milling!

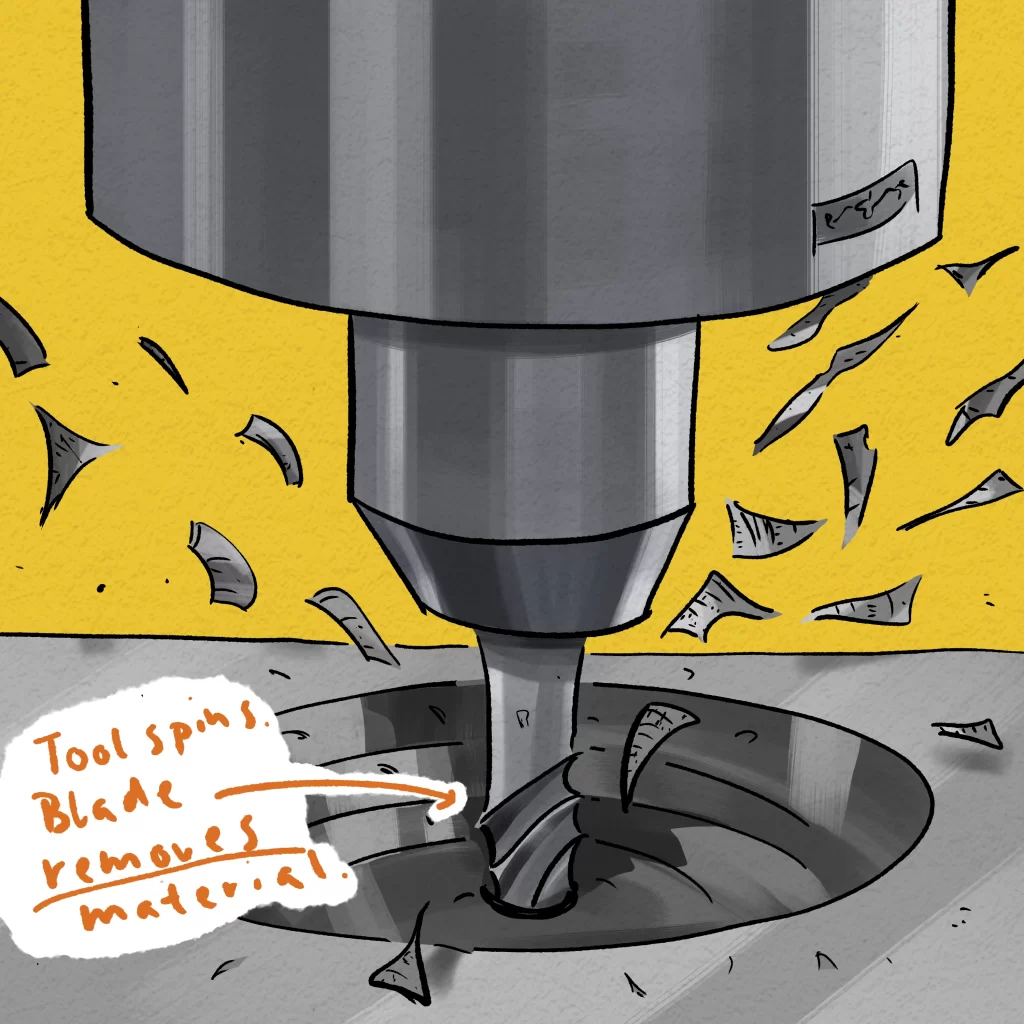

Milling is a subtractive process, meaning basically that you start with a big piece of material and remove bits of the material to leave what you want. (Many of the processes we’ll be discussing are subtractive.) This is in contrast to additive manufacturing, where bits of material are layered upon each other to form the desired item (like in 3D printing) or forming-type technologies, where the amount of material remains constant but it is molded into the desired shape, such as sheet metal forming or thermoforiming. (To be discussed in a minute.)

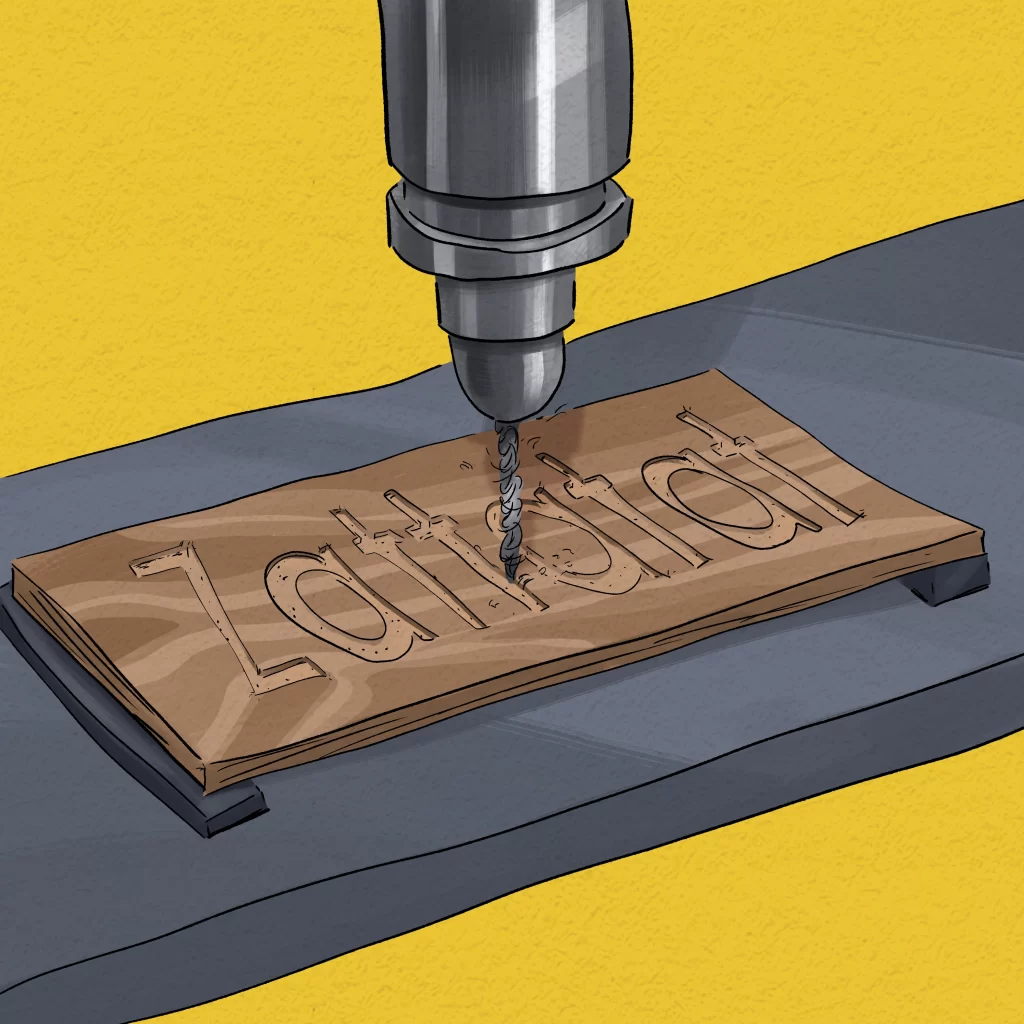

In milling specifically, the bit spins and sharp edges of the bit remove the unwanted material. Milling can be used with a variety of materials, but probably the most popular are metal, and wood. It’s less popular with ceramics because ceramics are brittle. Milling is more suited to ductile materials.

Rhonda was already familiar with milling and was happy to show the group an example from her workshop.

Gary, being sick of having Rhonda in the spotlight, asked Process Cat if he could now talk about something more in his area of expertise. Gary was expecting Process Cat to talk about something in the baking realm, but he instead suggested they discuss it…

Thermoforming!

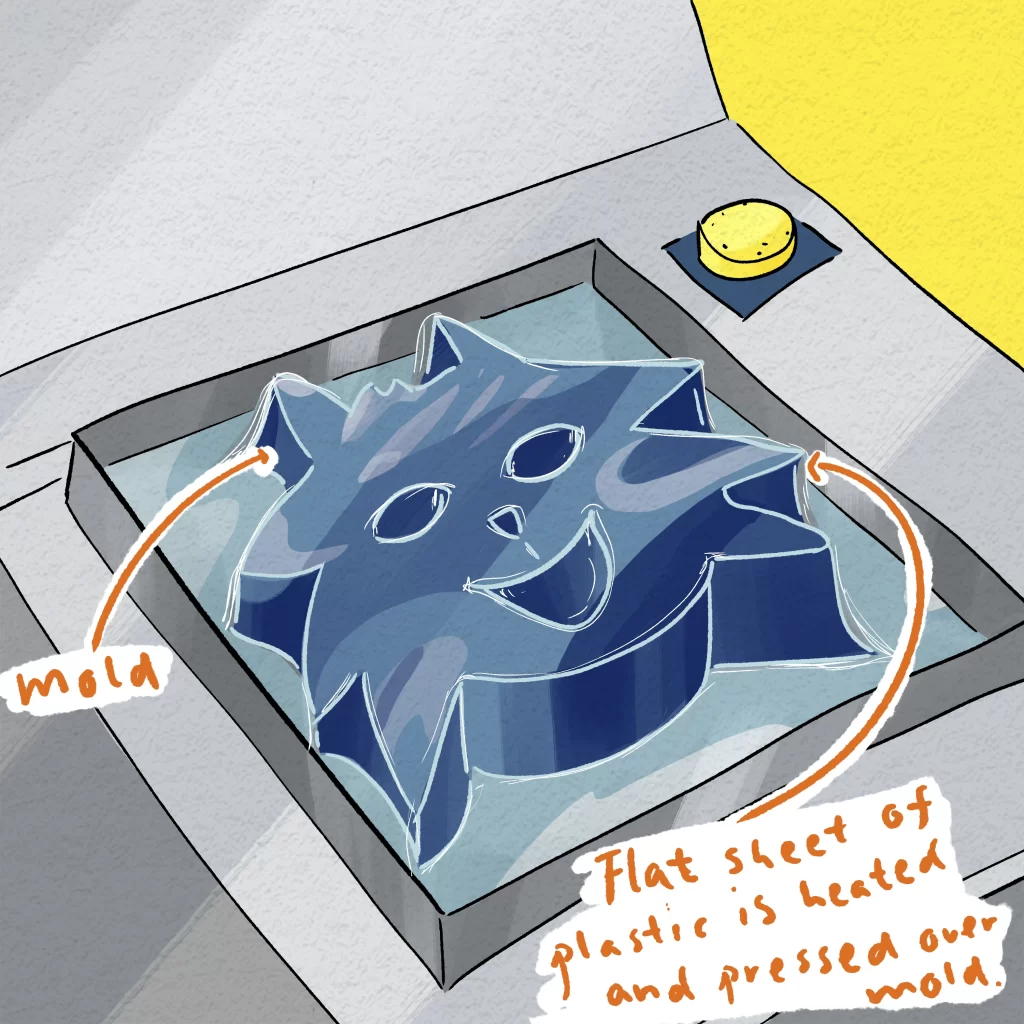

Thermoforming (sometimes called vacuum forming) is taking a sheet of plastic and, well-forming it around a mold using heat and/or vacuum.

But, even Gary wondered, what does this have to do with baking and bakeries?

Process Cat explained it is a technology that Gary has used indirectly. In that, he regularly purchases packaging made by thermoforming.

See, although in most of our process discussions baking is definitely in the realm of making and manufacturing, it’s actually more accurately classified as a chemical process versus a traditional manufacturing technology. So if Gary wants to one-up Princess Capybara with his manufacturing technology know-how, he may just have to wait….

Weekly Challenge:

Look around at things you use in your own business or even in your personal life. Can you identify some things that were probably milled and some that were probably thermoformed? It’s easier than you think once you know what to look for! And come back next time to learn the next few basic manufacturing technologies.

Ready to learn more? Read the next article in the series!